Knowing the composition of a food is not a simple task, although technological development has allowed remarkable advances. The implementation, combination and correct use of this new technology, as well as its application to specific situations, is of special value for engineering and, ultimately, for the food sector. INFINITIA has the methods and equipment necessary to take the “pulse” of food and describe its structure beyond the common limits.

If we were to create a tomato from scratch, we could never obtain the same version as the original. The reason lies mainly in the fact that we do not know many of its components, as well as their exact association and the interactions that can take place inside it. A food must be defined as a whole, or in other words, a food is a food matrix made up of all its components that may relate differently according to their quantity or other factors.

The process of food characterization is of great help in solving problems related to safety or quality during processing. It is also a factor to be taken into account in other scenarios that respond to different commercial strategies, such as providing added value to differentiate it from the competition. For example, the incorporation to the market of a new chocolate with less fat, but without losing the flavor and the creamy and consistent texture, characteristics provided by the fatty elements. INFINITIA has developed this process in a meticulous way and with a high level of accuracy that allows an almost intangible context and objective to become a visual element.

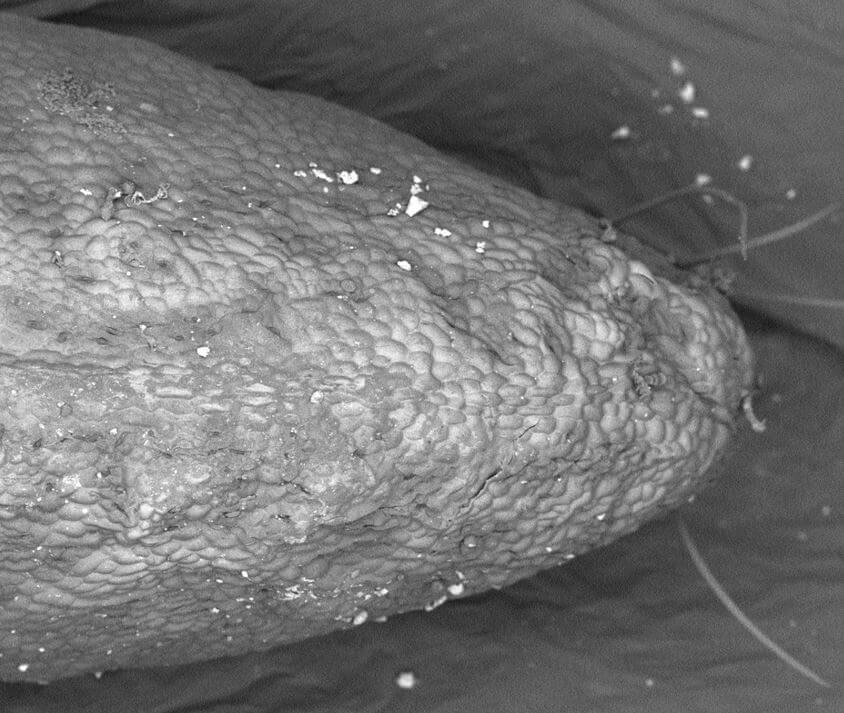

It is very similar to “a detailed photograph of the structure of a food”, explains Regina De Diego, a food engineer from this Aragonese consultancy. To get the “complete picture”, she points out that a particular and special set of instruments is necessary, so she emphasizes that “bringing together all the necessary tools to carry out this type of visualization of food matrices is not common”. However, INFINITIA’s commitment to cutting-edge technology and the constant search for solutions is once again evident, this time applied to the food sector.

The use of different and specific tools has become the winning combination to “go where others cannot in terms of characterization”, says Javier Sanz, CEO of INFINITIA. The set of instruments that offer this kind of “food radiography” is made up of three different pieces of equipment:

-SEM: high range scanning electron microscope that allows studying the microstructure of matrices such as emulsions or processed products as well as elemental composition on the surface.

-UPLC-MS: high performance liquid chromatography that gives the opportunity to study the presence and concentration of specific compounds always from liquid samples.

-GC-MS: Gas and mass chromatography that allows, like UPLC, the study of compounds but from samples in gaseous state, or semi-volatile compounds.

The human training for the application of this technology and its work together make it an almost unique method at the service of the industry. In the case of INFINITIA, it is put into practice through the expertise of De Diego, Elena Díaz de Marco and Silvia Pallaruelo, specialists in food engineering, nutrition and chemistry, respectively.

This service, characterized by being highly specific in its sector, can be used in all types of food, however, its combination will vary depending on the characteristics of the food.