Characterization of materials

The characterization of materials is a fundamental tool to ensure the highest quality in the design and manufacturing processes of new products. In Infinitia Industrial Consulting we carry out the characterization of materials to know their behavior and to be able to make the best decision in the industrial process.

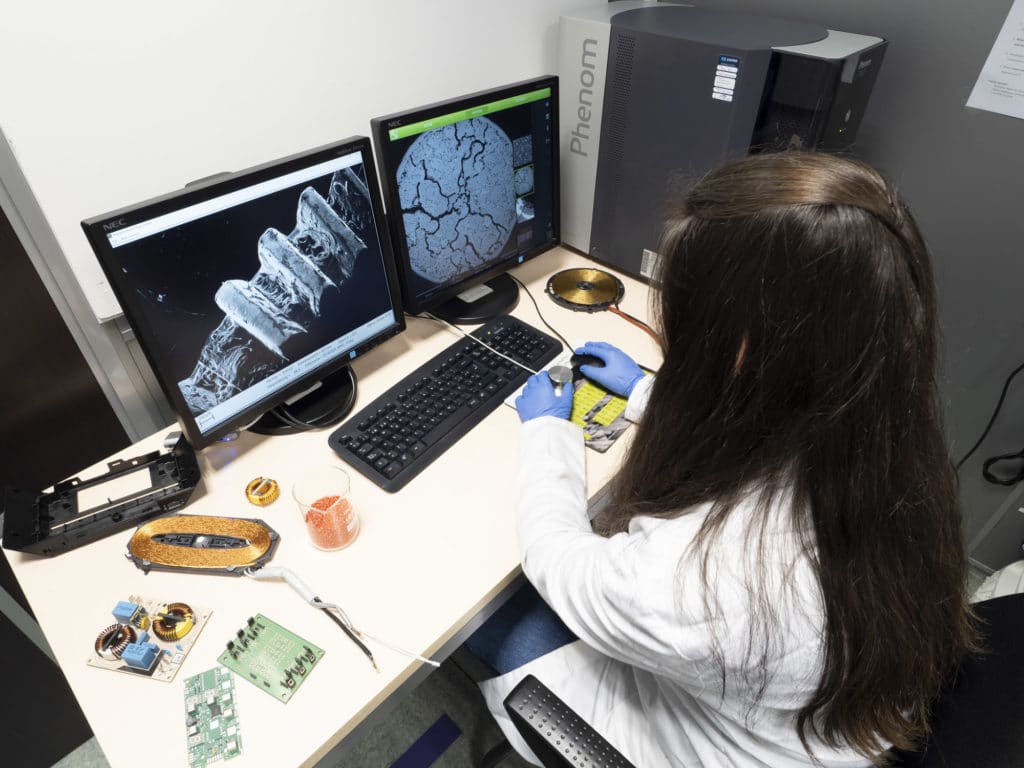

In our industrial laboratory we have a group of materials specialists working with the latest technology in characterization equipment and auxiliary and sample preparation equipment.

What is materials characterization?

Materials characterization is the procedure by which the morphological and functional properties of certain substances are studied. The aim is to obtain important information about the compounds, such as their degree of strength and reliability or their possible applications.

In this way, material analysis facilitates the characterization of the physical, chemical and mehcanical properties of the samples, which is indispensable for predicting the performance of the various elements and estimating the service life of the products based on the expected environmental exposure conditions.

Main material characterization techniques

The technological experiments used in the industry are very varied and include microscopic and macroscopic procedures, as well as destructive and innocuous tests. These are some of the most common material analysis techniques:

Spectroscopy

It uses the interaction between electromagnetic radiation and matter to define the structure and concentration of the chemical components of a sample. This is done by measuring the absorption, emission or scattering of energy in certain ranges of the electromagnetic spectrum. Variants include infrared, ultraviolet, laser, atomic absorption, X-ray and nuclear magnetic resonance spectrometry.

Fractography

This material characterization technique is based on the study of fracture mechanics. It is carried out by examining in detail the fracture surfaces of the materials, performing a stress analysis of the cracks and other existing flaws that helps to define the causes and nature of the mechanisms causing the damage.

Microscopic analysis makes it possible to obtain graphic records of the smallest structures of materials using technologically advanced microscopes. Optical microscopy, electron microscopy, tunnel effect microscopy or atomic force microscopy are some of the most common systems within the microscopic techniques for materials characterization.

It consists of the physical separation of the components of a mixture. For this purpose, the differences in the distribution constants of the elements between a stationary and a mobile phase are exploited. The different types include gas chromatography and high-performance liquid chromatography.

This material characterization technique encompasses resilience, hardness, fatigue, torsion, tensile, compression and bending experiments. It involves tests in which mechanical forces of different types are applied to check the durability and strength properties of substances…

This section includes procedures that measure the evolution of materials when subjected to temperature changes, but also the thermal disparities between the components themselves. Some of the methods used are differential thermal analysis, differential scanning calorimetry, thermogravimetric analysis, thermomechanical analysis or infrared thermography infrared thermography.

These are tests in which extreme environmental conditions of humidity or contamination are simulated to test their effect on materials. Corrosion tests can be carried out with salt spray, urban atmosphere, humid atmosphere or electrochemical corrosion.

Contact with us

receive a tailored professional response

Plastics characterization, among the most common laboratory services

These materials have an increasing presence in the industry, so the characterization of plastics is one of the most common analysis in our laboratories. Some of the most common material analysis and characterization techniques for plastics are mechanical, thermal, impact and accelerated aging tests.

Benefits of material analysis techniques for industry

The advantages offered by materials characterization are very important for the industry. The different analysis techniques are used in forensic engineering to obtain precise data on the structural characteristics and behavior of all kinds of compounds under different environmental conditions and stimuli.

They are used to choose the best raw materials, prevent accidents and improve efficiency in design and manufacturing tasks, thus extending the useful life of products and optimizing the resources available to companies.

In short, materials characterization is an essential research tool for achieving greater efficiency in production processes.

Consult our laboratory characterization service for samples and materials.

The characterization and laboratory analysis of samples and materials allow us to determine their composition, to better understand their properties, to check their compliance with regulations or to detect possible contaminants. Our laboratory team will determine which analyses and tests are necessary for each case.

Contact with us

receive a tailored professional response