Mechanical Development

What is Mechanical Development

At INFINITIA, we seek the global optimization of products through mechanical development. That is to say, our team works to reduce costs and times, perfecting in turn the parts and choosing the most suitable components.

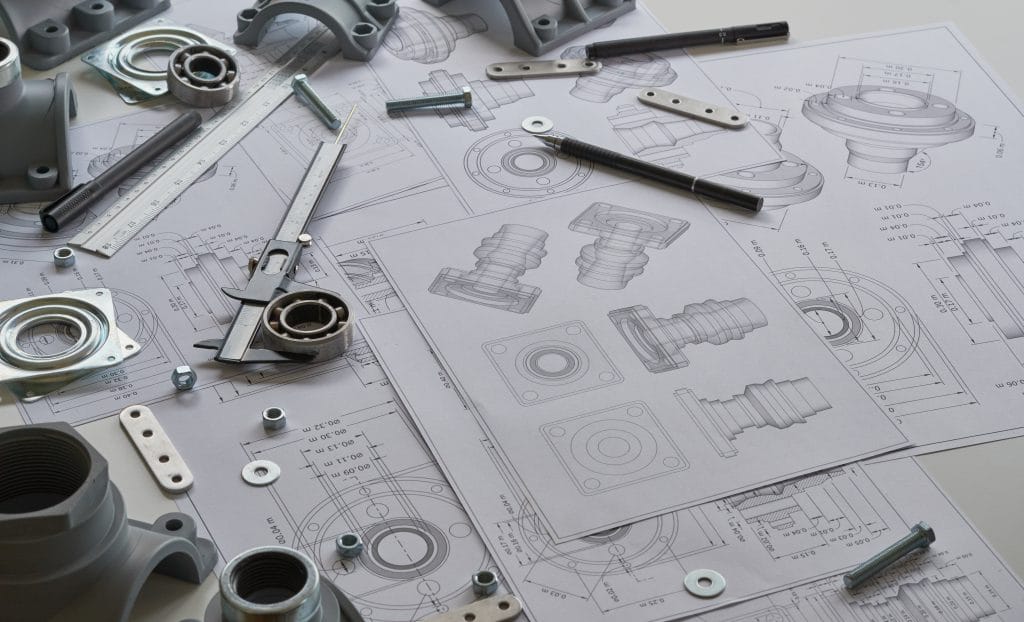

We manufacture short series prototypes, using an advanced design software. We render the plans, obtaining total precision in the design or redesign of the product.

We have our own resources. In our laboratory we are proactive, we anticipate possible failures and we implement the design of our parts, seeking maximum functionality.

Contact with us

receive a tailored professional response

How does INFINITIA approach Mechanical Development?

We put all our experience and training into your project. Ask us and we will make your idea feasible. We seek efficiency, above all, and that is why we work with a multidisciplinary team of professionals.

From taking the design forward, to optimizing the parts, to detailed component selection. Tell us what you need, and we will do the rest. We refine and improve the effectiveness of existing parts and, if it is necessary, design new ones from scratch.

At INFINITIA we work with rigour, seeking to manufacture products that are more profitable and bring greater benefits to your company. Investing in good mechanical development is synonymous with profitability. And that, as you know, is very important for any type of business.

Complete development

Once we have decided the work line to follow for the development of the selected concept, INFINITIA takes care of the complete development of your product, both aesthetically and functionally.

We completely cover the design of all the parts and components and we work hand in hand with companies specialised in hardware and software development so that the whole design works perfectly.

We validate each design using the latest rapid prototyping technologies before proceeding with the manufacturing with final materials and processes so that everything is 100% verified, reducing both deadlines and final investments.

CAD design

CAD tools allow us to implement a design more quickly and accurately. Long gone are the freehand designs of yesteryear, this is also what digitalization is all about: in the INFINITIA laboratory we use 2D and 3D graphic representations of objects to optimize our designs.

Optimal design for the mechanical development of our products is synonymous with strength, durability, and safety. We design your parts with precision and functionality.

Optimization of parts

At INFINITIA we reduce costs and time: we use methodologies capable of creating prototypes in the short term and at a lower cost than traditional methods.

Find out more about the mechanical development of your product at our engineering consultancy. We create new parts or optimize existing ones. Our experience makes us know the latest technologies and the different working sectors. We advise you, and at the same time we set your project in motion.

Design for manufacturing

When developing our designs, we take into account the final materials and production processes selected for each part and component, working directly with the final manufacturers and suppliers to ensure that all designs are 100% industrialisable.

We study the different design restrictions for each manufacturing process so that the proposed designs do not require subsequent modifications before their final manufacturing.

We are also used to working on existing designs, adapting them to specific manufacturing processes or proposing improvements or redesigns that guarantee that your designs can be manufactured industrially without any problems or unforeseen events.

Works done in Mechanical Development

Contact with us

receive a tailored professional response