Failure analysis

Common to all branches of the manufacturing industry, failure analysis is a discipline that determines the cause of a failure for products or equipment. The objective is to fix the problem and avoid further failures.

What is a failure?

Forensic engineering, as a branch of engineering, investigates the origin of a failure in a product or structure. A failure means the loss of characteristics or functions of a product or material due to various factors affecting the strength, stability, and chemical composition of the structure.

The reasons for it to happen can be multiple. It can be due to human errors or result from a mechanical origin. As the range of causes is so wide, engineering is required in the design of a component or structure to minimize the possibility of failure.

What is failure analysis?

In Infinitia, to find out the origin of a failure, we carry out a complete engineering failure analysis of materials and components that includes quality control in the production, the product, or the market itself. Our main objective is to identify the issue’s root for such an error not to occur again.

So, we investigate all its causes and consequences to establish responsibilities for possible production, manufacturing, transport, or sales errors. We discover how and why the failure occurred.

Goals for failure analysis engineering

Once again, the purpose of the failure analysis of materials and components as one of the stages of forensic engineering is to avoid the failure to be repeated. This main objective leads to smaller ones:

- Improve future products and processes.

- Prevent financial losses and penalties from failed components.

- Meet the standards for production.

- Determine liability for error.

The importance of failure analysis engineering

From Infinitia, we have noticed all these years that the most common failures affect the functionality and the quality of the final product. Most often, it means that a product is missing a part or, directly, it is misused.

However, it is not always the case. So, it is primordial to carry out a thorough analysis: components, composite structures, or manufacturing systems, among other things, are attentively examined. Thanks to our technical knowledge and great experience, we know how to conduct an effective failure analysis of materials and components. At Infinitia, we are highly qualified professionals.

The importance of failures modes

The best method to understand what caused the failure and to prevent it from recurring is failure modes. It exists several of them:

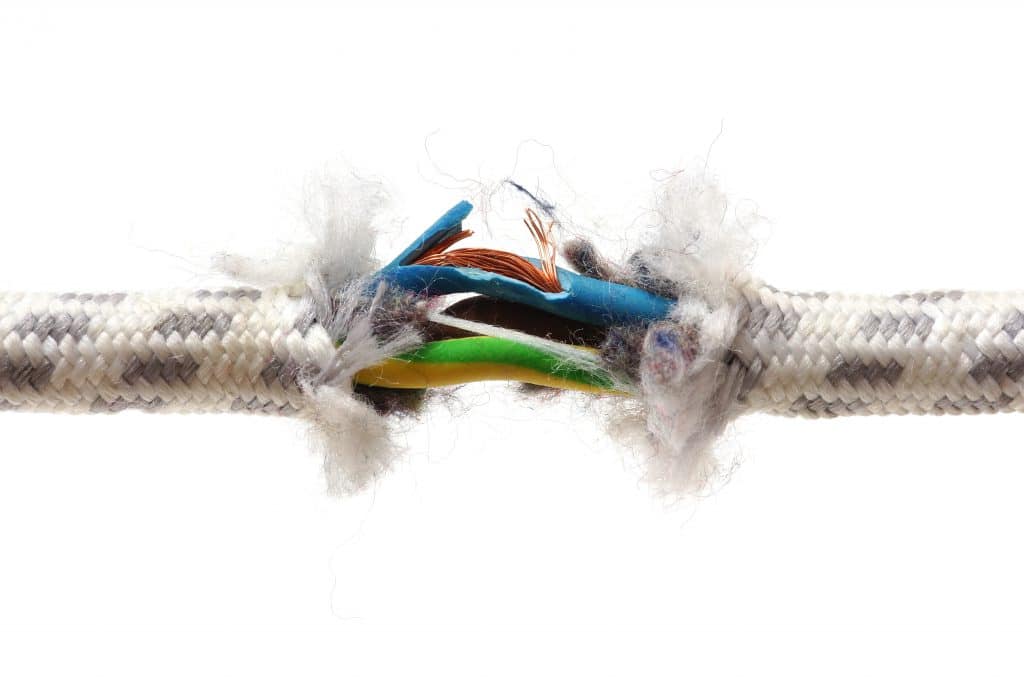

- Fatigue failure: the weakening of a material caused by cyclic loading. It includes mechanical, corrosion, and thermo-mechanical fatigues.

- Wear failure: it is caused by the effect of relative movement between surfaces or by contact between the surface and a substance.

- Corrosion failure: when metal atoms are detached from their structural element until it fails.

- Creep failure: the permanent deformation increases with time under a constant load or stress.

At Infinitia, our expert staff knows how to handle all failure modes to test materials and find the best solutions.

Phases in failure analysis

Here are the different phases to follow for performing a failure analysis engineering or in other words quality control in production processes, products, and markets.

Diagnosis

We start with a previous diagnosis. For this, direct and fluid communication with our customers is essential. We start to answer the big interrogation by going to the field for observation.

Hypothesis development and experimental validation

We set out our hypothesis and then test it. Assess the factors involved, and their relationship, through different methodologies. Science and previous experience are the keys to success in our research.

Risk analysis and implementation of solutions

Undoubtedly, proactivity goes with us. When we study the situation, we also analyze the possible risks and make a selection and implementation of the most optimal solutions to meet the needs of our customers.

How does Infinitia approach failure analysis?

We investigate the context and the situations produced to determine the mode and cause of failure in production, product, or market claims. We also provide key information for decision-making (e.g., in order to establish responsibilities, correct errors, etc.).

We interview different agents involved in the processes carried out, in order to gather as much information as possible and find the answer to the resolution.

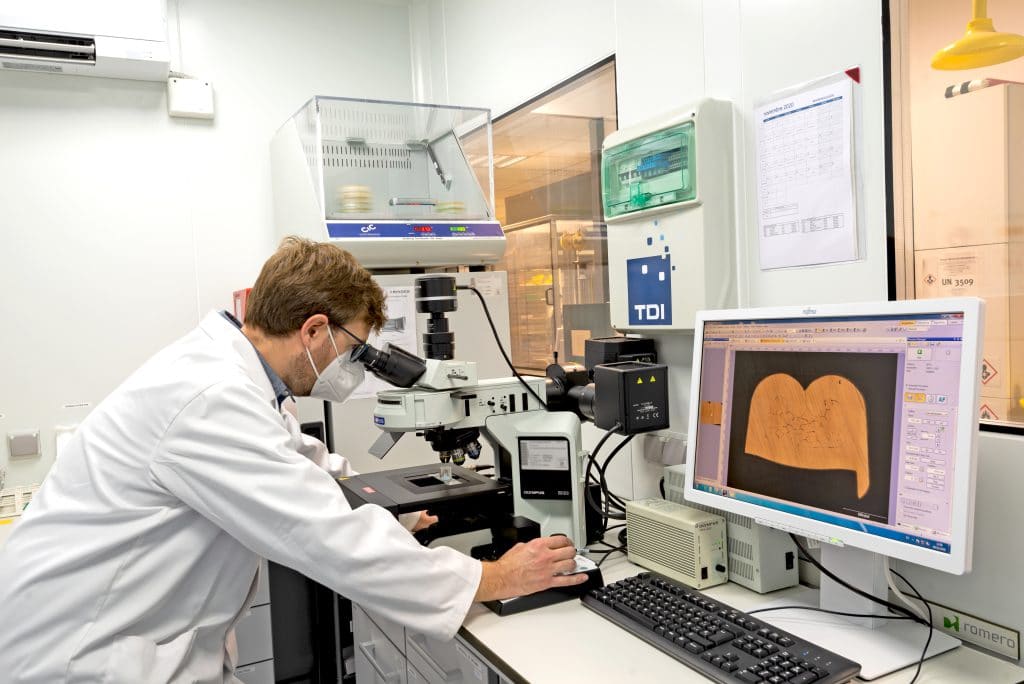

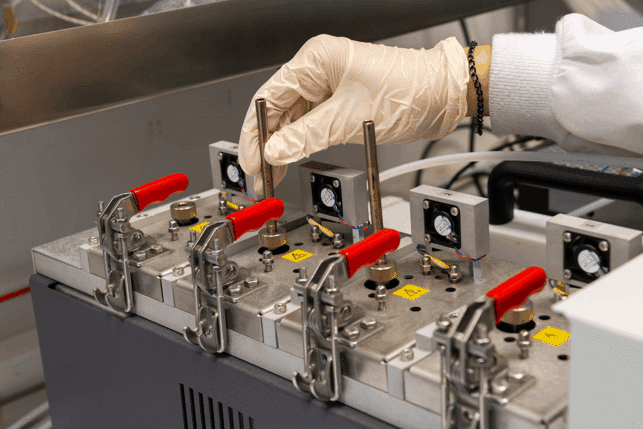

We analyze the materials with advanced laboratory techniques and instruments, in order to know their past, find traces, and clues, or detect improper uses in-market claims.

Production line failures

Performing analysis and control of the quality of production is very important since the vast majority of failures tend to occur in the value chain. These errors in production, the result of malpractice or machinery malfunction, can bring the entire chain to a standstill, resulting in large losses for the company. So, it is indispensable to lead our engineering failure analysis seriously and quickly.

For example, improper handling of raw materials during manufacturing can lead to contaminated, broken, or corroded parts that have to be removed from the entire production process. Also, one of the worst scenarios we have seen is when a machine malfunctions and injures a worker.

Therefore, from Infinitia, we are part of the quality control of the production of your company. We guarantee safety and rigor in the analysis of failures to prevent their occurrence or that they never happen again.

Product failures

Once the product has been manufactured, it may present a series of errors in its composition or physical appearance. The failure analysis of materials and components does not only cover the production process, our team also exhaustively analyzes the final result or product.

A product can present different aesthetic flaws such as discoloration of the paint, sudden wear, or premature aging, among others. This kind of failure can seem harmless. Nevertheless, if a company seeks customer loyalty should never occur.

From Infinitia, we see and analyze what defaults your product has to help you correct them, and thus, offer the best to your clients.

Market claims

The third scenario that we observe in our highly qualified technology laboratory is that of market claims. It means that claims occur once the product has been put on sale.

These failures are mostly due to incorrect use by users. From a discolored garment because it has been washed at a higher temperature, to a damaged washing machine due to the use of the wrong detergent. The reasons are numerous.

As the causes can be many and very different, our team works in a thorough and detailed way. We offer you a complete and very useful failure analysis to cover all possibilities.

Failure analysis engineering is key for forensic investigations. It is an indispensable phase to identify the failure and its causes for preventing it to repeat and, inevitably, improving the products.