What was the challenge or problem to solve?

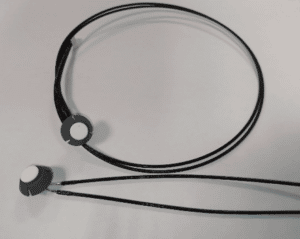

The customer requested to evaluate the thermal influence on the elongation of cables and controllers as a function of the temperature of their product by analysing samples from different suppliers.

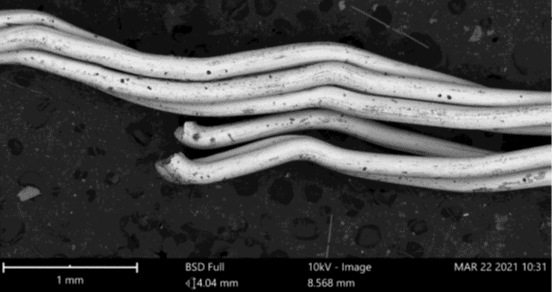

When subjected to high temperatures, such cables were mechanically deformed, causing a risk of loss of functionality of the product, leading to a safety failure that could affect its users.

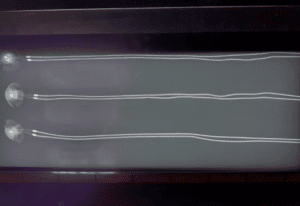

It was decided to evaluate the influence of high temperatures on the material. To do this, the Forensic Engineering team had to design a new method that would allow for a rigorous quantitative and comparable assessment. This methodology was used to investigate how heat affects the length of the cable.

Experiments helped to determine that cables from a certain supplier subjected to high temperatures suffered a sudden contraction of their length. As a result, a buckling effect appeared in some cases through permanent buckling of the cable, leading to brittle fracture of the cable.

Challenge

- Development of a new methodology to evaluate the thermal influence and elongation with respect to time.

- Design of experiments to evaluate the parameters of interest.

- Quantitative control of deformation and temperature.

Solution

- Comparison of the behaviour of each material under real operating conditions.

- Selection of the optimum alternative for this application, based on the knowledge acquired for this type of cable.