What was the challenge or problem to solve?

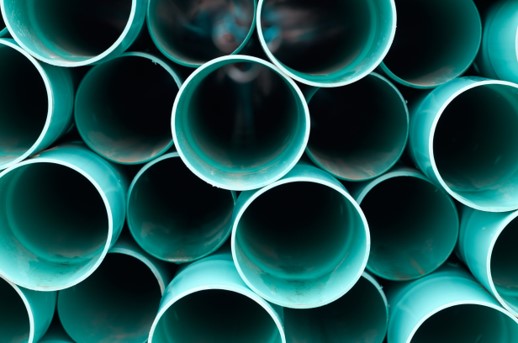

There are few plastics that can withstand long exposure to weathering because it needs to have a specific composition and characteristics.

The objective was to perform a reverse engineering process of this unknown material, to know its composition, and with the information extracted, the client could improve its product.

How was it addressed or what was the solution?

The forensic engineering team analyzed the material using various techniques to obtain as complete a characterization of the material as possible.

It was found that the material was composed of two polymers that were very similar chemically, but that their use together improved their separate properties.

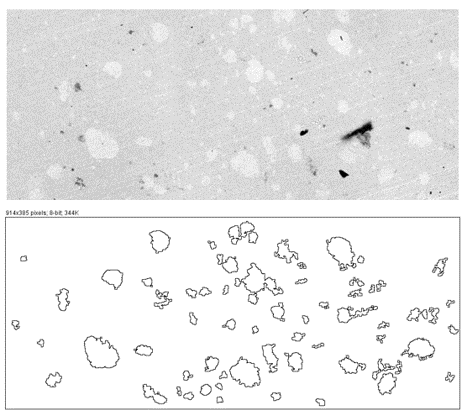

Among all the analysis techniques, an image treatment by scanning electron microscopy (SEM) was performed, and a study of the surface was carried out to determine the amount of elements present in the material.

Challenge

- Finding a material resistant to weathering conditions

- Characterize an unknown material

- Determine the proportions of the compounds that are part of the material

Solution

- Reverse-engineer an existing material on the market that meets the desired requirements.

- Employ various complementary analytical techniques

- Use an image processing program