What was the challenge or problem to solve?

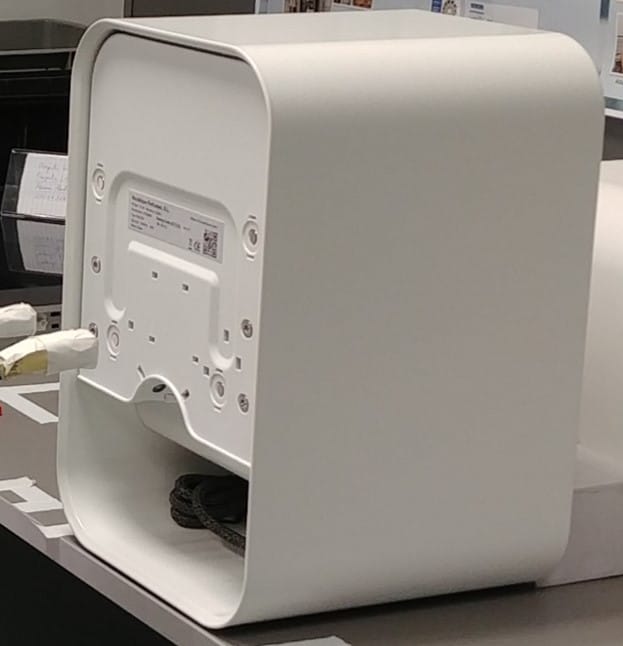

The process required performing repetitive cycles simulating the habitual use of the device by a user, to simulate component wear and detect possible product failures.

The number of cycles to be performed amounted to more than a million per device, which made it impossible to perform them manually.

How was it addressed or what was the solution?

The challenge was addressed through the use of collaborative robots, with which it was possible to carry out tests with high repeatability, determining the exact number of cycles.

This process allowed to measure the wear of the pieces each desired number of cycles of the program.

Challenge

- Determine the lifetime of the mechanical parts as a whole of a final product.

- Perform numerous repetitive life cycles.

Solution

- Use of collaborative robots to replicate the common use of the device.

- Exact control of the number of cycles of use of the product.

- Complete autonomy in the tests.