What was the challenge or problem to solve?

Our Product Development team faced the challenge of the integration and validation of technologies in already established machines, seeking not only the effective incorporation of the new technology but also its optimal compatibility and operation with the original system. The project focused on modifying a line of machines for a client, with the aim of validating the technical viability of this innovation, ensuring that the necessary changes did not affect the original performance of the machine.

The development began with a thorough analysis of the existing information and the specific needs of the project, followed by a detailed study of the technology to be implemented and the operation of the target machine. This preliminary analysis was crucial to establish the technical and functional requirements of the prototype, ensuring a solid foundation for the development. Through technical meetings with the client’s R&D department and the use of 3D models of the original machine, uncertainty was minimized, and a clear framework for the prototype development was defined.

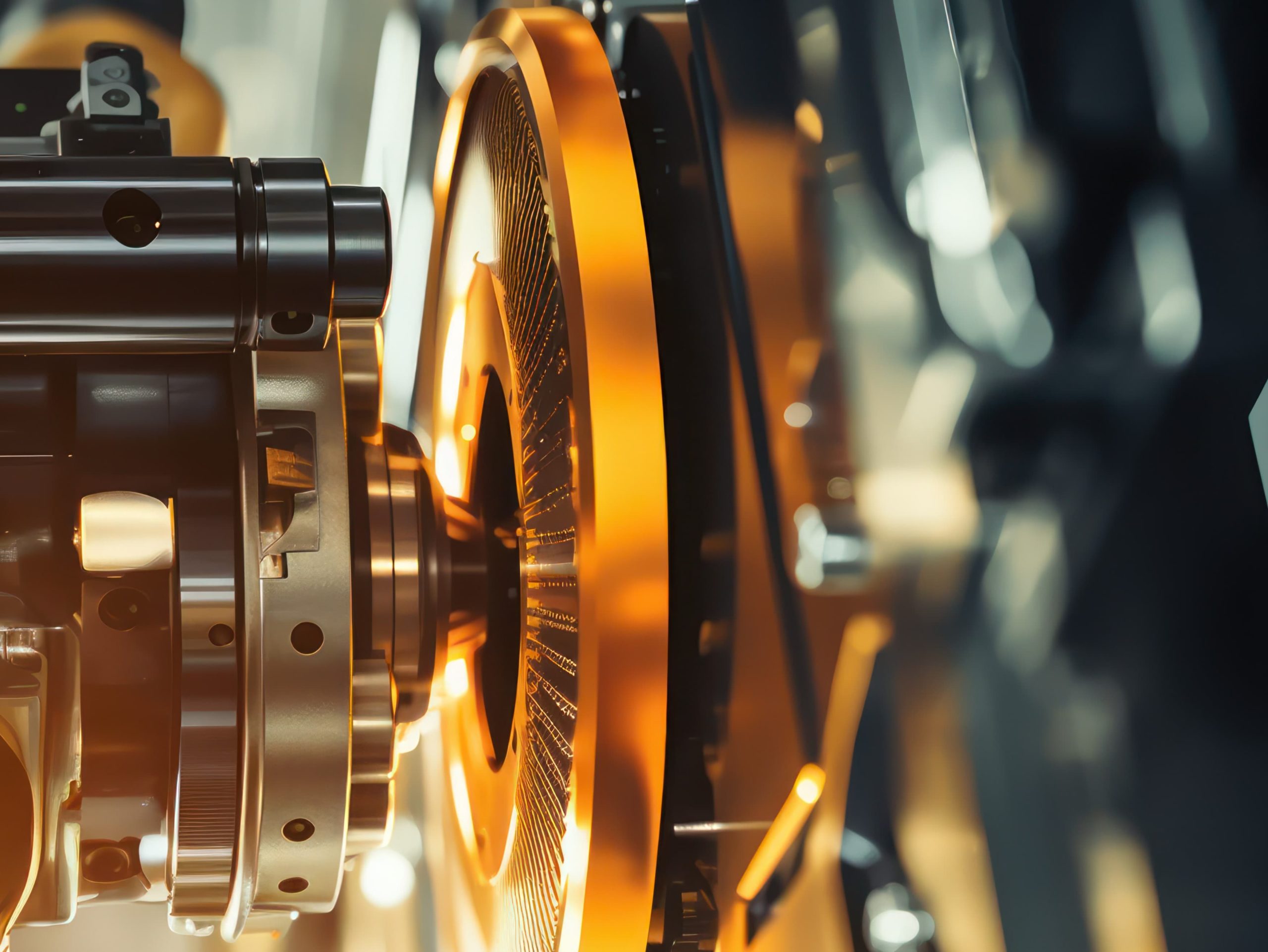

The design of the necessary components was performed using 3D modeling, followed by their manufacture through DLP 3D printing and machining of aluminum parts, ensuring high precision. Each component was subjected to independent tests to verify its functionality before being integrated into the machine, thus facilitating the final assembly and ensuring the effective adaptation and integration of the proposed technology.

Finally, mechanical and structural modifications were made to the machine, integrating the new components and the technology to be validated. It was then that exhaustive laboratory testing was achieved.

The final tests not only confirmed the correct operation of the assembly but also validated the effectiveness of the incorporated technology, demonstrating to our client the feasibility of creating a new line of innovative products, significantly improving their performance and opening up new possibilities for use.