What was the challenge or problem to solve?

In one product, stainless steels were found to have yellowed, which is known as thermal staining, due to the use for which it was used, as high temperatures were maintained. In addition to seriously deteriorating the aesthetics of the product, the appearance of these stains implied more difficulty in cleaning and corrosion problems in the laser marking areas.

Since there was no technical solution for these requirements on the market, INFINITIA’s materials innovation team worked together with the customer to achieve an aesthetic and high temperature resistant finish, with an acceptable thermal tinting, managing to solve the problems with the aesthetic finish and functionality.

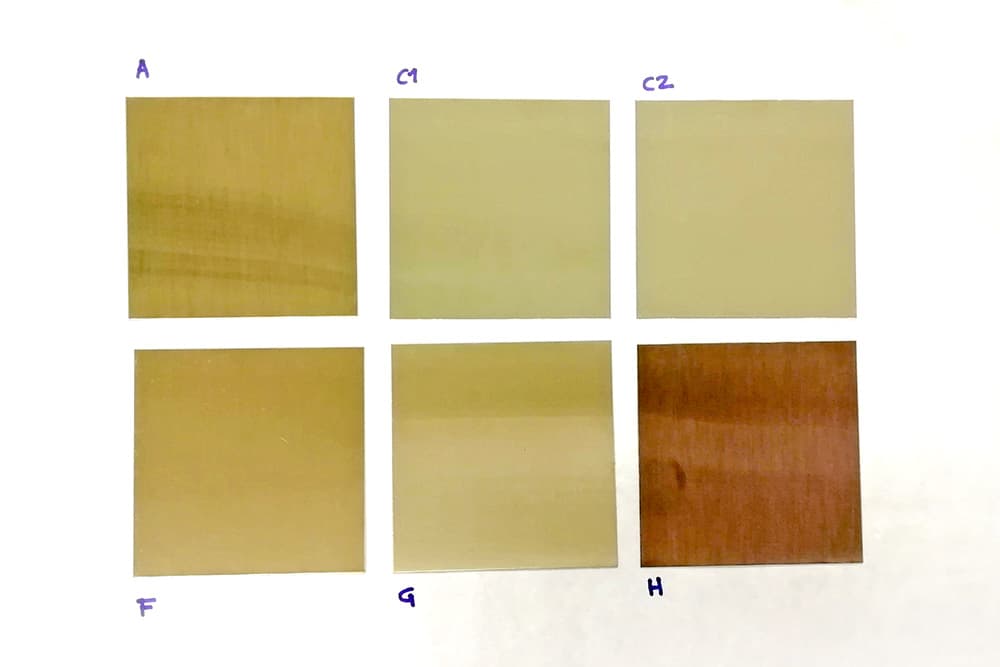

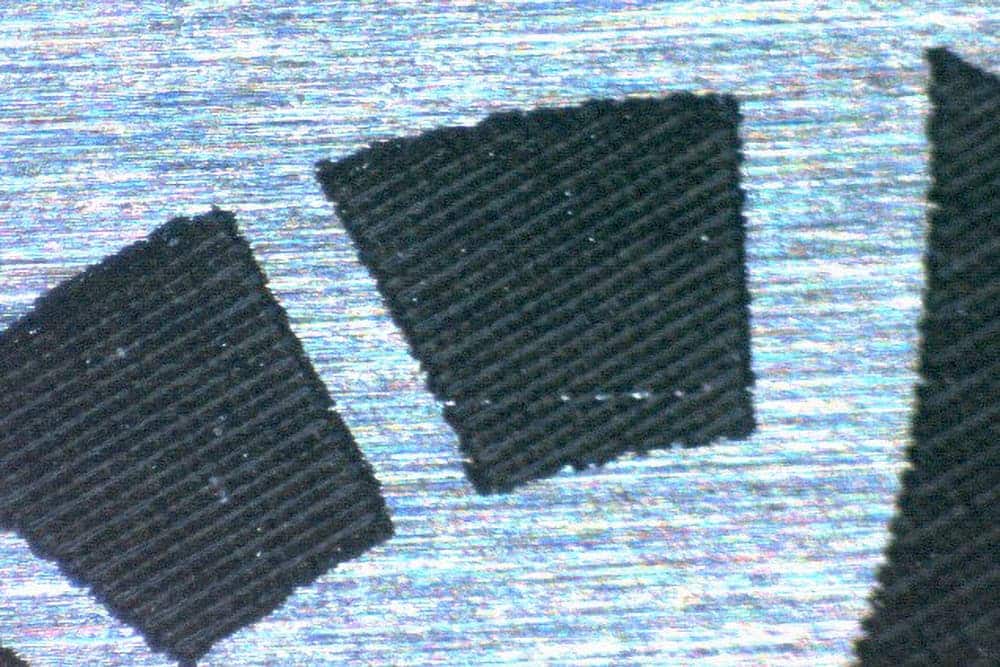

First of all, we carried out a comparison of the original parts of the different steels studied by means of a visual analysis. This process was documented with high quality photographs taken with a reflex camera. We also carried out a visual comparison of the laser-marked areas with the aid of an optical microscope. In this way, the critical areas were inspected thoroughly and with a high level of detail.

We then proceeded to study the colour in the yellowed areas and in the different test tubes. For this purpose, an analysis was carried out using a portable colorimeter.

A crucial factor for the improvement of the material was to know the corrosion resistance of the samples. For this reason, a corrosion study was carried out using a potentiostat. Another decisive aspect in this project was aesthetics, so we carried out a study of the product’s visible surface, both before and after yellowing. A profilometer was used to accurately measure the roughness of the material.

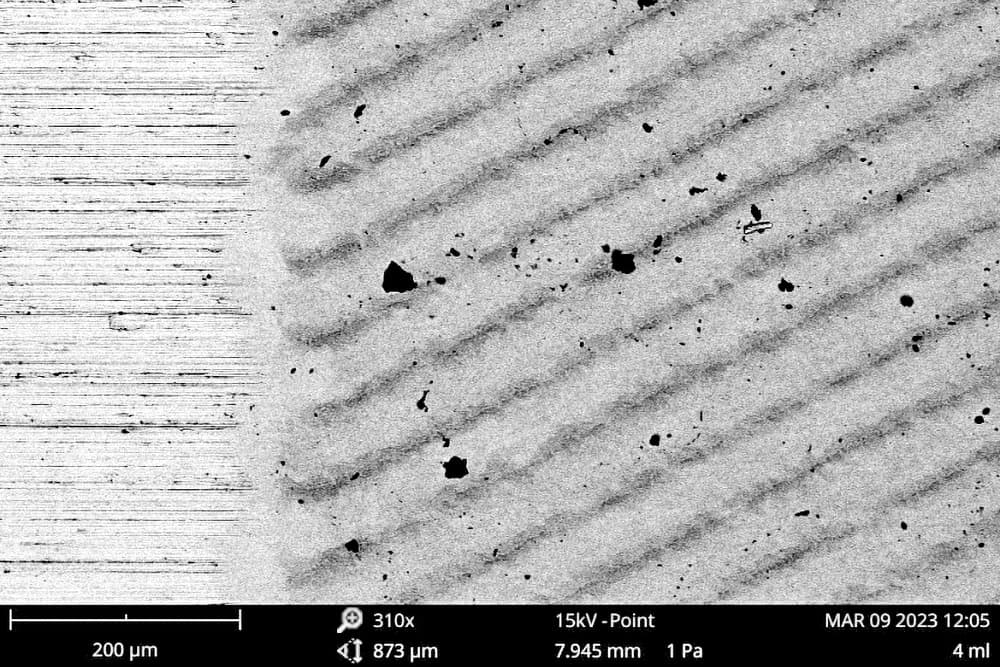

Finally, we carried out an inspection using a scanning electron microscope and metallography. This test allowed us to identify the characteristics of the microstructure and to compare the differences between the samples before and after yellowing.

From all these tests we were able to determine the causes of the degradation of the material and, therefore, to look for alternatives that would meet the customer’s requirements.