The potential of 3D printing is almost unattainable, as the market has evolved technologically in recent years. The financial audit firm E&Y published in a report that there was a 41% increase in participants using 3D technologies for additive manufacturing. This is not a new technology because 3D printing has been on the market for several decades, but it is true that its development has been experienced thanks to software and hardware.

What is 3D printing for?

One of the main advances is the ability to create solutions that meet customer requests. We must not forget the fact that additive manufacturing affects the supply chain, especially the storage of parts.

Producing a detailed drawing to produce solids with volume is considered a 360-degree turnaround in the design industry, and there is a process history that allows for modifications to be made at any time.

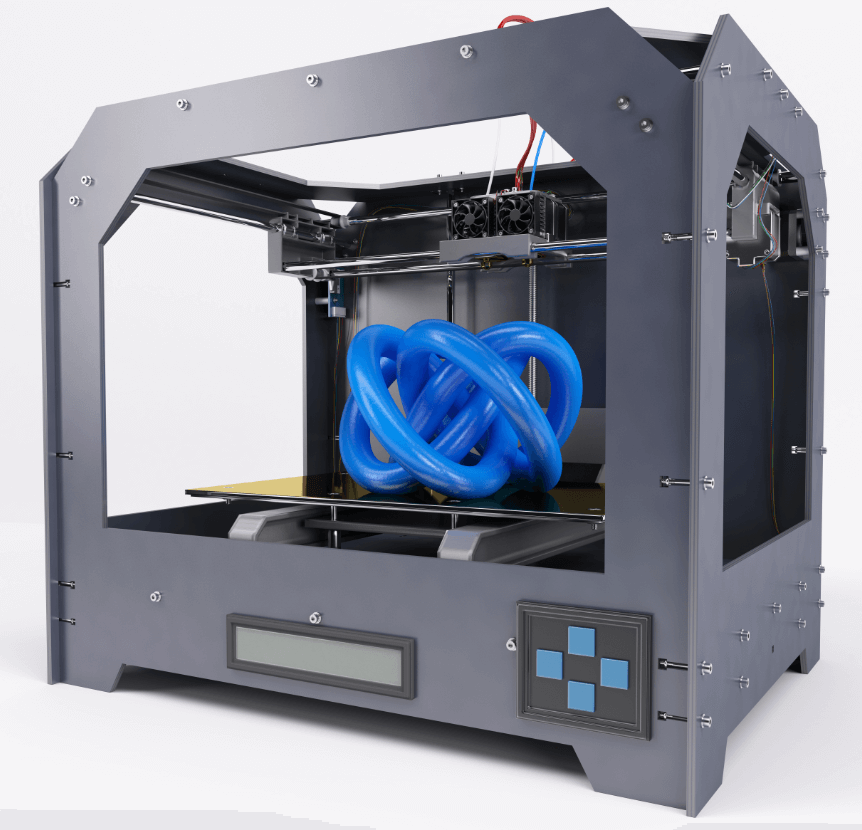

The main feature that differentiates 3D manufacturing from what we could call “the one of a lifetime” is the way in which the element is built. Additive methods build objects by adding material layer by layer, placing them in the form of thread or powder. However, the “traditional” way develops the pieces through a mold. In practice this disparity translates into considerable savings, because it reduces material waste almost to a minimum.

How Infinita applies 3D printing

For Infinitia, an industrial engineering startup, this process is a major contribution to additive manufacturing that is fully effective in its strategic design and prototyping area, as it allows the product manufacturing process to be streamlined. The 3D printing accepts a greater number of interactions and this allows to manufacture prototypes or demonstrators more efficiently, as well as anticipating the competition in the market. “An advantage to be taken into account in a globalized market where the introduction of new products or adaptations is constant,” says Javier Sanz, CEO of the company.

In addition, other advantages are the low cost in the creation of pieces and the specialized and custom-made work strategy. The elaboration of pieces can be personalized. “It allows us to achieve a very high level of personalization, as we can design each piece individually,” explains Sanz, in this sense even “we are able to improve your design from scratch and turn a piece or product into scalable when it was not previously,” he says.

The sectors that most demand this technology are the automobile, aeronautics, and even the food sector, where in recent years countless companies have emerged that are using 3D printing to print food and even cook it later.

What is the future of 3D printing?

The short-term future for the implementation of 3D in the industry is promising. It is estimated that almost 50% of the manufacturers, according to different market studies, will use this type of technology and that the related business will grow considerably to almost 19 billion euros.

The industrial sector is then in luck because it could be possible to develop new materials; to improve the machines in terms of speed, price and software; also to increase the number of printed parts that will exceed the development applications. Processes in which Infinitia has the experience and background necessary to provide a rapid and effective response.