Industrial design is a fundamental part of creating and developing new innovative products and materials with better properties and more efficient uses. In this post, we will explain what industrial design is and what is its process.

What is industrial design?

Industrial design is a discipline that deals with the creation and development of products, starting with the conceptualization of an idea and continuing with the manufacturing and mass production process.

It is a multidisciplinary subject and encompasses multiple areas, such as product design, design engineering, components, vehicles, structural design, prototype simulation, etc. Moreover, design is an activity that is constantly evolving with the world and is a participant in its evolution. An example of this is eco-design, a new way of understanding design that harmonizes the needs of the environment and industry in an innovative way.

The objective of industrial design is to identify a market opportunity or product development, improvement and innovation, as well as to define the problem faced, develop an appropriate solution through its creation and validate the solution before its mass production and on a large scale.

Finding the solution that best fits the needs of the industry requires a process consisting of several phases, known as the design process.

Design process

Every product design starts with an idea. The hard part, and the most interesting part, is bringing it to life.

During the development process of a new product, different factors are taken into account, such as the necessary materials, machinery, budget, current market trends, user needs, reception, feasibility, project deadlines, ergonomics, functionality or resistance to the passage of time, among others. All these elements are structured in a series of steps that we will see below.

1. Defining the product vision and strategy

Every design project needs a product vision and a strategy to set the direction and guide the design team. The vision captures the essence of the product, the critical information that must be known to develop and launch a successful product. It is about answering the questions what is to be built and why to establish clear solution boundaries and thus define a roadmap that maintains focus.

2. Product research

Once the product vision is defined, it is necessary to carry out a thorough research work. This stage includes everything from market and trend research, regulatory research to product functionality, ergonomics and safety to maximize the likelihood of success before any decisions are made.

3. User analysis

The objective of the analysis phase is to draw conclusions from the data collected during the product research phase. Capture, organize and make inferences about what users want, think and need.

4. Ideation

In this stage, team members think of creative ideas that address the project objectives. It is critical not only to generate ideas, but also to confirm that the design assumptions are valid.

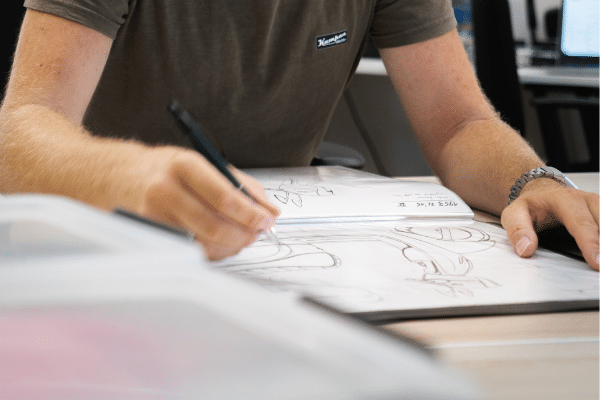

There are many techniques for ideation, from sketching, which is very useful for visualizing what some aspects of the design will look like, to storyboarding, which is used to visualize the overall interactions with a product.

5. Design and prototyping

After the conceptualization phase, when you have a clear understanding of what you want to build, you will begin to implement the concepts through its creation, trying to solve the problem that was raised at the beginning through prototyping.

strategic design and prototyping is essential to offer a good user experience. Prototyping should be part of the design process. A prototype is an experimental model of an idea that allows it to be tested before it is built and manufactured in series. A prototype grows in breadth and depth over multiple iterations and it is the final version of a prototype that is delivered for development.

When it comes to prototyping, efficiency is vital and the most efficient process is rapid prototyping, whereby solutions can be created, reviewed and tested saving time and money.

6. Testing and validation

The testing and validation phase ensures that the design concept works as intended, has passed all tests and meets expectations and will therefore lead to the manufacturing and industrialization of the product.

7. Mass production and industrialization

Once all the previous phases of design and development of a product have been completed, it is time to officially launch it to the market and start mass producing it for sale, distribution and implementation.

Undoubtedly, innovation, development and creation of new products and more efficient materials would not be possible without industrial design. At Infinitia we know how important it is, that is why we have one of the best strategic design and prototyping teams. Contact us without obligation.