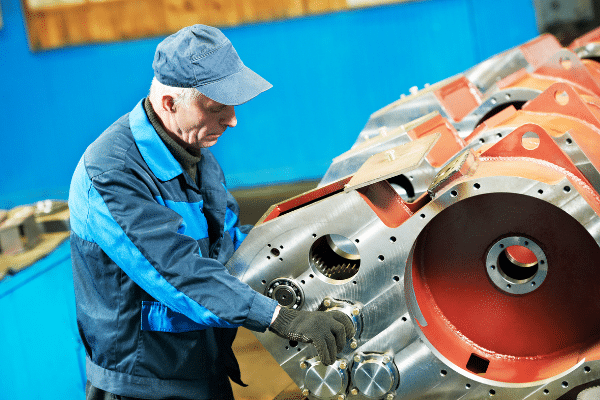

Assembly design techniques facilitate the assembly of a product, thereby reducing costs and minimizing the number of operations required. In this article we explain what assembly is and the principles of assembly design.

What is assembly design?

Assembly design is a design process or concept that focuses on the manufacturability and efficiency of assembling a product with a minimum number of parts.

By simplifying the design it is possible to manufacture and assemble it more efficiently, in the shortest possible time and at a lower cost, improving the reliability and quality of the product.

It is therefore a matter of selecting the most cost-effective materials and processes for production and minimizing the complexity of manufacturing operations to facilitate the assembly of a product. Similarly, it makes it possible to identify, quantify and eliminate waste or inefficiency in manufacturing.

Assembly design techniques can be executed by specific processes such as machining, die casting or injection molding and are applied to sectors as diverse as the industrial design of automotive and consumer products, which need to efficiently manufacture high quality products in large quantities, or sectors such as construction, for the manufacture of concrete slabs, columns and structural beams.

It is certainly used in a multitude of industrial sectors to achieve improved assembly of components, more efficient functionality or to correct faults, for example, in the redesign of plastic components for subsequent manufacturing and industrialization. In the following, we will see what are the principles on which the design of assemblies is based.

Principles of assembly design

Minimize the number of components

Using fewer parts reduces assembly and ordering costs and simplifies the assembly process and automation.

Design for ease of part manufacturing

Part geometry is simplified and unnecessary features are avoided. Thus, components are designed so that they can only be assembled in a single way.

Minimize the use of flexible components:

Rubber parts, gaskets, cables, etc., should be limited in assembly processes, as their handling and assembly are often more difficult.

Design for ease of assembly

The use of snap fasteners and adhesives is preferable to more complex shapes such as bolts and nuts. Similarly, a product should be designed with components that are easy to locate for quick and accurate assembly to other components. In this sense, modular design translates into ease of assembly and cost reduction.

Use of the same parts and fasteners

It may not be possible to reduce fasteners completely, but at least use the same type of fastener for the entire product. This applies not only to a particular object or product, but also to common parts across the entire product line to create an efficient assembly design.

Eliminate or reduce the adjustments needed when assembling

Designing fits into a product means that there are more opportunities for mismatch conditions to arise. Likewise, it is necessary to keep in mind that assembling or disassembling components should not be a puzzle.

Fasteners

Conventional fasteners account for up to 50% of a product’s assembly time. However, it is possible to reduce assembly time by incorporating fasteners directly into the parts.

Advantages of assembly design

Some of the main advantages of assembly design are the following:

- Increased speed in product construction due to the use of prefabricated elements.

- Ease of assembly

- Reduced material costs, assembly costs and labor costs.

- Increased reliability by reducing the number of parts, which reduces the possibility of failure.

- Reduced assembly time, as the transition from design to production is as quick and smooth as possible.

- Increased quality and sustainability by using an automated approach improving quality and efficiency at every stage of design and prototyping.

Need to design a product efficiently? Contact our strategic design and prototyping team and tell them about your case.