Biodegradability, Compostability, and Recyclability Testing

At INFINITIA, we offer a comprehensive service for biodegradability, compostability, and recyclability testing designed to meet the current sustainability requirements of the industrial sector.

This service allows us to scientifically validate whether a material or product is suitable to be considered biodegradable, compostable, or recyclable according to international standards.

Through laboratory testing, standardized methodologies, and controlled environments, we evaluate the behavior of materials at the end of their useful life, providing essential data for strategic decisions in design, manufacturing, or regulatory compliance.

In our industrial laboratory, we have specialists in sustainable materials and advanced analysis technologies that allow us to reproduce real or accelerated conditions of decomposition and recycling, both in aquatic and terrestrial environments, as well as in industrial or domestic composting environments.

At INFINITIA, we promote sustainable innovation through rigorous technical validation of eco-friendly materials.

What are biodegradability, compostability, and recyclability tests?

Biodegradability, compostability, and recyclability tests consist of a series of standardized tests that determine the extent to which a material decomposes naturally, whether it is compatible with composting processes, or whether it can be effectively reincorporated into production cycles through recycling.

At INFINITIA, we apply methodologies such as testing according to ISO 14855 (aerobic biodegradation under controlled conditions), EN 13432 (compostability of packaging materials), and mechanical and chemical recyclability protocols according to the specifications of each material.

We analyze the chemical composition before and after testing, CO₂ production, mass loss, degree of disintegration, and the quality of the resulting compost or recycled material. These types of tests are essential for validating bioplastics, compostable packaging, or recyclable plastics, and for ensuring their performance in accordance with circular economy and environmental sustainability criteria.

Benefits of biodegradability, compostability, and recyclability testing

One of the main benefits of these tests is the ability to validate and justify, with verifiable technical data, the sustainability of a product or material.

At INFINITIA, we help companies anticipate regulatory requirements, facilitate environmental certifications, and make informed decisions about new product development or the replacement of raw materials.

For example, by performing an industrial compostability test on a packaging film, it is possible to demonstrate its decomposition without leaving toxic residues, facilitating the obtaining of environmental seals and improving the perception of the product in the market. Similarly, by analyzing the recyclability of technical plastics, we identify improvements to facilitate their separation and reprocessing.

This type of testing also allows us to detect materials with residual ecotoxicity or low efficiency in recycling processes, adding value to product redesign and sustainability strategies.

Sustainability testing at INFINITIA

At INFINITIA, we carry out biodegradability, compostability, and recyclability testing under strict technical and scientific protocols. We have facilities equipped to reproduce conditions of decomposition in soil, aquatic environments, or in composting plants, whether industrial or domestic, in accordance with EN 14995, ISO 20200, and ASTM D6400 standards, among others.

Our engineering and laboratory team carries out a complete analysis of the chemical composition before and after the test, monitoring the evolution of the materials and conducting accelerated studies when evaluation times need to be reduced.

In addition, we prepare rigorous technical reports that certify the sustainable performance of materials, raw materials, and approval processes, both for internal validation and for third parties.

Our approach combines regulatory knowledge, forensic engineering, and advanced characterization technology, providing companies with a solid foundation for decision-making and continuous improvement of their sustainable solutions.

Types of Biodegradability, Compostability, and Recyclability Tests

At INFINITIA, we perform different types of tests to evaluate the performance of materials and products at the end of their useful life, whether through natural decomposition, composting, or recycling. Our goal is to validate their sustainability under international standards, anticipating their environmental impact and facilitating decision-making in design, production, and regulatory compliance.

Biodegradability tests under controlled conditions

These tests measure a material’s ability to decompose through the action of microorganisms under aerobic or anaerobic conditions, in environments such as soil, fresh water, or sea water.

We use standards such as ISO 14855, ISO 17556, and ASTM D6954 to simulate real or accelerated scenarios.

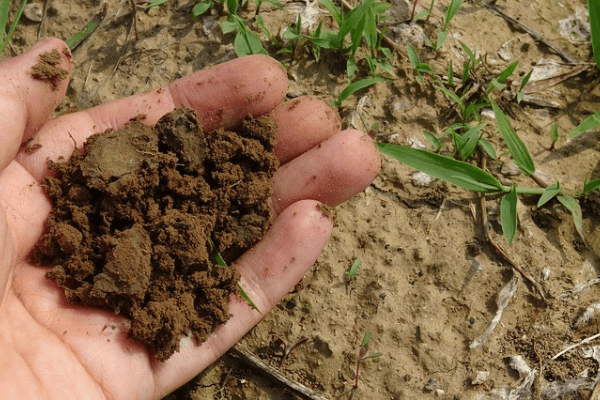

These analyses are essential for validating biodegradable plastics and innovative materials intended for disposable applications. At INFINITIA, for example, we have evaluated the biodegradation rate of bioplastics in soil by simulating humidity and temperature conditions.

Industrial and domestic compostability tests

We validate whether a material degrades completely during the composting process, without leaving toxic residues or affecting the quality of the resulting compost. We apply standards such as EN 13432, EN 14995, ISO 20200, and ASTM D6400.

We measure physical disintegration, biological biodegradation, and ecotoxicity. In a recent case, INFINITIA tested compostable packaging films, validating their performance in industrial facilities and domestic composters under real conditions.

These tests analyze whether materials can be reincorporated into mechanical or chemical recycling processes while retaining their functionality. They include separation, cleaning, reprocessing, and recycled material evaluation tests.

At INFINITIA, we develop recyclability tests for multilayer packaging and complex materials, in accordance with UNE-EN 15343 standards and other technical guidelines, detecting incompatibilities or barriers to circular recyclability.

Disintegration and mass loss tests

We evaluate the physical decomposition of the material in composting, soil, or water environments. We apply standards such as ISO 20200 and ISO 16929, measuring the percentage of fragmentation after standard cycles.

These tests are key for compostable packaging. At INFINITIA, for example, we have verified the disintegration of materials in composters, guaranteeing the absence of residues after the process.

Determination of chemical composition (pre- and post-testing)

We analyze the composition of materials before and after the degradation or recycling process, using techniques such as FTIR, TGA, or chromatography.

This allows us to detect non-biodegradable residues, contaminants, or structural changes.

At INFINITIA, we have characterized the presence of additives, heavy metals, or persistent compounds in degraded samples, validating the safety of the resulting compost or recycled material.

Ecotoxicity testing and environmental impact assessment

We validate that materials do not release toxic substances that could affect microorganisms, plants, or earthworms. This includes seed germination, plant growth, and toxicity in treated soils tests.

At INFINITIA, we apply these tests to biodegradable packaging projects to ensure the environmental safety of the compost generated, complying with the criteria of EN 13432.

Applications of Biodegradability, Compostability, and Recyclability Tests

Material sustainability testing is essential to ensure the transition to circular economy models in multiple industries. Through standardized tests, INFINITIA helps companies validate sustainable materials, optimize designs, justify environmental claims, and ensure regulatory compliance.

These analyses are particularly relevant in sectors where the use of plastics, packaging, or single-use materials is intensive, and where there is growing regulatory and market pressure to replace traditional materials with biodegradable, compostable, or recyclable alternatives.

Packaging Industry

In the packaging sector, sustainability has become an essential requirement. Manufacturers are looking for materials that decompose into industrial compost, are recyclable, or can be integrated into separate collection systems.

Testing allows the performance of these materials to be validated during use and after disposal, in compliance with standards such as EN 13432 or ISO 20200.

- Validation of industrial compostability of multilayer films through disintegration, biodegradation, and ecotoxicity testing.

- Evaluation of mechanical recyclability of rigid packaging, including its compatibility with separation and industrial reprocessing systems.

- Determination of biodegradation in soil for packaging or single-use items designed to degrade after use.

Agroindustry and Agriculture

Intensive agriculture generates large volumes of plastic waste such as mulch, pots, nets, and protectors. Replacement with biodegradable alternatives requires demonstrating that these products degrade in the soil without generating toxicity or interfering with crop cycles.

Biodegradation testing under controlled conditions and post-degradation residue analysis are key.

- Biodegradability assessment of films under simulated conditions of temperature, humidity, and soil microbiological activity.

- Ecotoxicity tests to ensure that the compost or waste generated does not affect soil fertility or living organisms.

- Measurement of mass loss and fragmentation after a complete cycle of agricultural use, validating the disappearance of the material without external intervention.

Cosmetics and Wellness Sector

The cosmetics industry is incorporating sustainable packaging as part of its environmental and differentiation strategy.

These materials must demonstrate their compostability or recyclability without affecting consumer safety or the environment. In addition, they must comply with specific regulations on contact with active substances.

- Home compostability tests for solid cosmetic packaging, single-dose capsules, or secondary packaging elements.

- Migration analysis of organic compounds after material decomposition to ensure the absence of hazardous residues.

- Recycling validation of plastic components such as lids, jars, or dispensers, evaluating their reprocessing and structural purity after several cycles.

Technical Textiles and Sustainable Fashion

Sustainability in fashion and technical textiles involves developing fibers and fabrics that can degrade under natural conditions or compost without leaving toxic residues.

Tests make it possible to quantify the rate of decomposition, the ecotoxicity of residues, and their impact on ecosystems.

- Compostability assessment of textile fibers in composters.

- Aquatic biodegradation tests to validate technical textiles exposed to marine, river, or humid environments.

- Ecotoxicity analysis of composted waste on seed germination and plant development, complying with the requirements of standards EN 13432 and ASTM D5338.

Appliances and Consumer Electronics

Electronic devices and appliances incorporate numerous engineering plastics that, once they reach the end of their useful life, must be integrated into recycling chains. Recyclability validation allows materials that maintain their properties after reprocessing to be selected.

- Recyclability testing of housings, connectors, and internal parts through simulation of industrial processes.

- Compatibility analysis between recycled and virgin polymers to validate their mixing and performance in subsequent applications.

- Assessment of the impact of additives, pigments or fillers on the quality of the recyclate and its suitability for new use cycles.

The importance of biodegradability, compostability and recyclability testing

In a context where sustainability is no longer an option but a requirement, biodegradability, compostability, and recyclability testing have become essential tools for ensuring that the materials used in industrial products comply with objective environmental and regulatory criteria. At INFINITIA, we offer these tests as part of a comprehensive product validation and improvement strategy geared toward the circular economy.

Thanks to our experience in technical analysis of materials and specialized equipment, at INFINITIA we not only evaluate the behavior of materials at the end of their useful life, but also interpret the results in terms of real application, environmental impact, and industrial viability. The data obtained allows us to justify decisions in product development, facilitate certification processes, detect limitations of current materials, and propose more suitable sustainable alternatives.

The demand for compostable and recyclable materials is growing in all sectors: from food packaging to technical textiles and electronics. Therefore, having a laboratory capable of performing tests according to standards such as ISO 14855, EN 13432, or ISO 20200 translates into a tangible competitive advantage. At INFINITIA, we combine technical knowledge with an applied vision, adapting each test to the specific needs of the product or sector, always with the scientific rigor that characterizes us.

In addition, we see a clear trend toward the adoption of stricter regulations and the growing importance of eco-design. The products of the future must be designed to be properly managed at the end of their life cycle. That is why, at INFINITIA, we are working today with the technologies and criteria that will be indispensable tomorrow.

Counting on INFINITIA to carry out these tests means having a reliable technical partner, capable of providing real solutions, solid data, and personalized advice at every stage of the development of sustainable materials. Our commitment is to help companies innovate responsibly, safely, and in line with the challenges of today’s environment.