In April, the Spanish Congress of Deputies approved the Law on Waste and Contaminated Land. The aim is to prevent and reduce the impact of certain plastic products on the environment, thus moving towards sustainable products and a circular economy. “The law, which is ambitious, proposes a separation between household waste, textiles, oils, hazardous waste, bio-waste and construction material. This is something that is already being done, but more resources and containers are provided for it,” says Javier Sanz, CEO of INFINITIA.

The regulation was created to comply with European objectives in terms of sustainability. The European Union imposed more than a decade ago that all its members should recycle 50% of their municipal waste by 2020. However, at that date, Spain was at 36%, according to Eurostat data. The new regulation bans the marketing of certain single-use plastic utensils such as straws, cups and plates, as well as creating a tax on them. In this way, reusable alternatives or alternatives made from other components will be promoted.

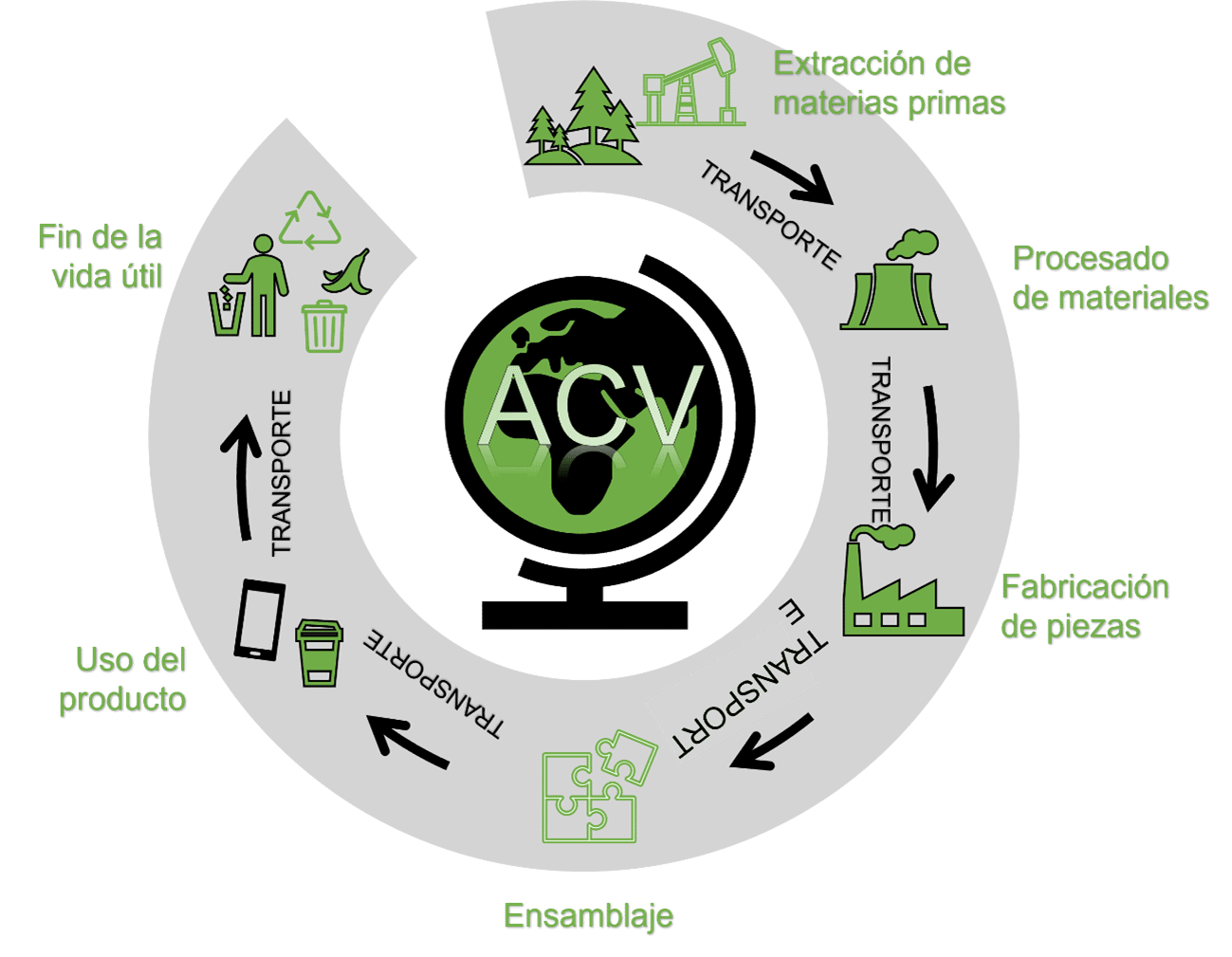

However, to measure the lifespan of any product, it is important to use life cycle analyses. “They are the study of the overall life of a product,” says Eva Pacheco, polymer consultant at INFINITIA. “They cover everything from where the raw material is extracted to the production, maintenance, reuse and recycling processes; in other words, how it is deposited in a landfill and what is done with it once its useful life is over.

Along these lines, Pacheco has reviewed some analyses of the life cycles of products made with alternative materials to plastic, including paper, tetrabrik, bioplastics, aluminium and wood. “The conclusions say that the problem of waste management is still there. Even if you have a material that is not made of plastic, if it is a single material, you are still going to have to manage that waste; it can be reduced by changing the material, but it does not disappear. The management problem is still there,” he explains. For this reason, he advises that “we should not replace one material with another, but reduce the use of disposable products“, as “it is the optimal thing to do according to the life cycle analysis”.

Things change when the material is reusable, as this is when “the impact is reduced”. On the other hand, according to Pacheco, “sometimes plastic is even better, as it is lighter and more compact than cardboard, for example”. “Overall, there is not that much difference between plastics and other alternative materials if the product is single-use,” she says.

As for the Waste Law, he said that “it focuses on reducing the use of plastic, but it does not address the fact that its alternatives are probably not as good from an ecological point of view“. “With the proposal, you reduce having to deal with plastic waste and prevent a lot of it from ending up in the sea, but if you encourage the use of only one material, that other material also has to be managed in some way because otherwise it will end up in the same place,” she says.

At INFINITIA, we are responsible with the selection of product materials. In this way, we offer the possibility of rethinking the design so that these products are, from the moment they are made, sustainable and, therefore, easily separable and recyclable once their useful life is over.

“It is not a question of demonising plastic because it is a good thing. You can optimise the characteristics of the product so that you don’t need to use so much or make something thinner. Also, there will always be alternative materials, which can be considered depending on the needs and end use of the product,” concludes Sanz.

If you are thinking of developing your product and you want to do it in a sustainable way, also thinking about its reuse and recycling, please contact us. We will be happy to advise and help you.