Analysis of galvanized, anodized and coated materials

The analysis of galvanized, anodized, and coated materials is a key process for ensuring the durability, corrosion resistance, and surface quality of metal components in demanding industrial environments.

At INFINITIA, we understand that surface treatments such as galvanizing or anodizing not only serve an aesthetic purpose, but are also essential for protecting materials against phenomena such as humidity, thermal changes, abrasion, or exposure to saline atmospheres.

In our industrial laboratory, we have a team specializing in the study of metal coatings that works with state-of-the-art technologies to validate the effectiveness of these treatments, identify failures, and ensure compliance with international standards.

Thanks to a scientific and multidisciplinary approach, at INFINITIA we carry out comparative and validation tests that allow our customers to optimize the selection of coatings, improve production processes, and reduce costs associated with premature failures.

What does the analysis of galvanized, anodized, and coated materials consist of?

The analysis of galvanized, anodized, and coated materials consists of rigorously evaluating the thickness, adhesion, uniformity, and resistance of the coatings applied to metal parts.

At INFINITIA, we perform specific tests such as accelerated corrosion, salt spray, climatic chamber, and thermal shock tests, which reproduce extreme service conditions to predict the actual behavior of a coating in less time.

This approach allows us to compare different finishes and select the most suitable one according to the conditions of use: from protective coatings in marine environments to high-strength aluminum anodizing for aeronautical applications.

The results obtained are included in comprehensive technical reports that serve both for supplier approval and for the continuous improvement of manufacturing processes.

Benefits of analyzing galvanized, anodized, and coated materials

One of the main benefits of this service is the ability to prevent critical failures before the product reaches the market. In sectors such as automotive, energy, and construction, a coating failure can lead to accelerated corrosion, loss of mechanical properties, or even serious structural failures.

At INFINITIA, we have seen how preventive coating analysis has enabled our customers to reduce claims, increase component life, and ensure regulatory compliance in highly regulated markets.

For example, simulating saline environments using a fog chamber has allowed us to anticipate the deterioration of galvanized coatings used on outdoor metal structures, providing specific data to improve corrosion protection processes.

Coating analysis at INFINITIA

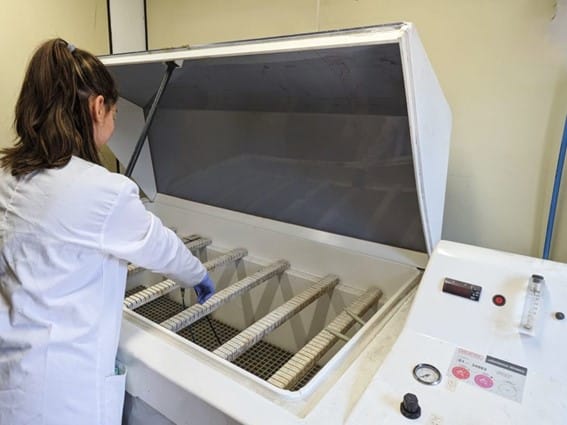

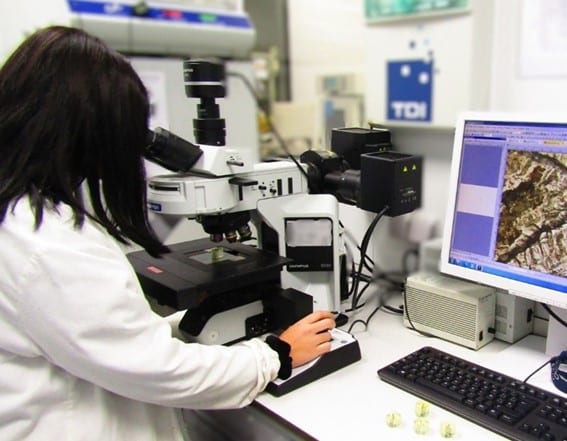

At INFINITIA, we take a comprehensive approach to the analysis of galvanized, anodized, and other coatings. We have equipment such as programmable climatic chambers, salt spray testing systems, thermal shock equipment, and advanced microscopy to characterize both the surface and microstructure of the coating.

In addition, we apply forensic engineering methodologies to diagnose failures in parts in service, identifying the causes of degradation and proposing improvements in materials or processes.

Our laboratory combines standardized testing according to ISO and ASTM with customized tests tailored to each client, allowing us to offer precise technical solutions tailored to the real needs of each industrial sector.

With INFINITIA, companies find a strategic partner to ensure the quality, durability, and reliability of their coatings.

Types of Tests for Galvanizing, Anodizing, and Coatings

At INFINITIA, we develop different tests to evaluate the performance and durability of metal coatings applied to industrial components. Our goal is to accurately determine the resistance of each coating under real conditions of use, optimizing its application, functionality, and service life.

Accelerated corrosion tests

These tests intensively reproduce the effect of corrosion on galvanized and anodized coatings. Specific chambers are used to simulate extreme conditions of humidity, salinity, or contamination.

At INFINITIA, we use tests such as salt spray and cyclic corrosion to predict the deterioration of coatings in less time. A common case is the comparison of galvanized finishes on structural parts to select the one that best withstands aggressive marine or industrial environments.

Salt spray tests

The salt spray chamber allows metal coatings to be exposed to an atmosphere containing chlorides. This test validates the oxidation resistance of galvanized, anodized, or protective coatings.

At INFINITIA, we have subjected automotive coatings to salt spray tests to determine which finish offered the greatest corrosion protection without increasing manufacturing costs.

Climatic chambers reproduce controlled temperature and humidity cycles to evaluate the behavior of coatings in response to environmental changes.

At INFINITIA, we apply these tests to electrical components and metal structures to study degradation, cracking, or loss of adhesion.

Thermal shock tests

This test exposes parts to sudden temperature changes to study the resistance of coatings to thermal stress. It is used on aluminum anodizing and highly demanding technical coatings.

At INFINITIA, we have validated the dimensional stability of aeronautical coatings after cycles of extreme cold and intense heat.

Thickness and adhesion measurement

The quality of a coating depends on its thickness and adhesion to the substrate.

At INFINITIA, we perform destructive and non-destructive measurements to verify that they comply with technical specifications. This control is critical in supplier approval and production series validation.

Applications of Coating Analysis

The analysis of galvanized, anodized, and coated materials has key applications in multiple industrial sectors. At INFINITIA, we help validate suppliers, select optimal coatings, and anticipate failures under real-world conditions.

Automotive Industry

In the automotive industry, components must withstand aggressive environments, vibrations, and thermal cycles.

- Validation of galvanized coatings on chassis and frames subjected to salt spray.

- Aluminum anodizing tests on engine and body parts.

- Evaluation of protective finishes against humidity and temperature cycles.

Construction and Infrastructure

Metal structures exposed to the elements require coatings that ensure their structural integrity for decades.

- Accelerated corrosion testing on galvanized profiles for facades and roofs.

- Climate chamber testing for metal panels in urban and marine environments.

- Validation of anti-corrosive coatings on bridges and civil engineering works.

Energy Industry

Energy equipment such as wind towers and offshore installations are exposed to highly corrosive atmospheres.

- Comparison of galvanized coatings on wind towers using salt spray.

- Validation of anodized coatings on hydraulic and solar turbine components.

- Thermal shock testing on energy components subjected to sudden changes.

Electronics and Household Appliances

In this sector, in addition to resistance, coatings also serve an aesthetic function.

- Thickness and uniformity control in decorative metal coatings.

- Adhesion testing on anodized aluminum parts.

- Evaluation of corrosion resistance in housings exposed to moisture.

Aerospace and Defense Sector

Aeronautical or defense coatings must maintain their integrity under extreme conditions.

- Thermal shock testing on structural anodized aluminum.

- Validation of technical coatings using microscopy and electrochemical corrosion.

- Comparative evaluation against temperature cycles.

The added value of INFINITIA in the analysis of galvanized, anodized, and coated materials

The analysis of galvanized, anodized, and coated materials is an essential service for all companies seeking to guarantee the quality, durability, and reliability of their products in demanding industrial environments.

In sectors such as automotive, construction, energy, electronics, and aeronautics, a coating failure can lead to serious economic and technical consequences. Therefore, having a specialized laboratory such as INFINITIA represents a clear competitive advantage.

At INFINITIA, we integrate different testing methodologies—such as accelerated corrosion, salt spray, climatic chamber, and thermal shock—with precise thickness and adhesion measurements, offering a complete overview of the actual performance of coatings. Our approach combines scientific characterization with forensic engineering, allowing us not only to validate finishes and approve suppliers, but also to diagnose service failures and propose technical solutions to prevent future incidents.

Current trends point towards sustainable, high-performance coatings with advanced functionalities (antibacterial, hydrophobic, self-cleaning). In this context, INFINITIA positions itself as a strategic partner capable of accompanying companies in the transition towards innovative solutions adapted to the challenges of modern industry.

In short, choosing INFINITIA to carry out the analysis of galvanized, anodized, and coated materials means ensuring rigorous validation processes, anticipating critical failures, and optimizing product life. Our commitment is to add value to each project, transforming technical data into practical decisions that reinforce the quality, competitiveness, and reliability of companies in the industrial sector.