Chemical analysis of metals

The chemical analysis of metals is an essential service to guarantee the quality, reliability, and safety of the materials used in industry. At INFINITIA, we offer this service to respond to the growing need to characterize and control the composition of metals and alloys, ensuring that they comply with technical specifications and current regulations.

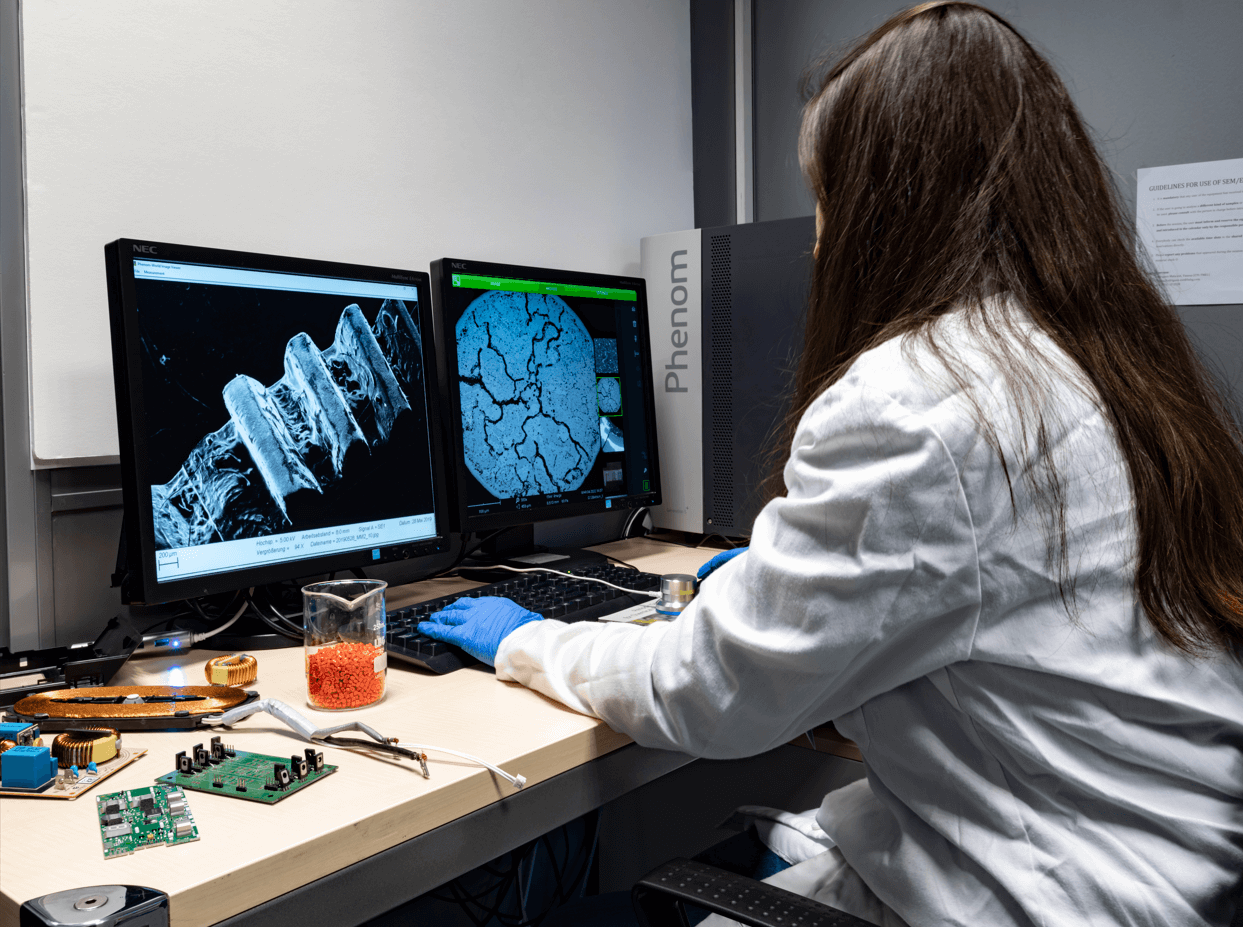

In our industrial laboratory, we have a team of specialists who use advanced technologies such as ICP-OES, ICP-MS, SEM-EDX, and XRF, allowing us to analyze in detail the composition of steels, aluminum, copper, titanium, and other critical alloys for sectors such as automotive, construction, and energy.

Thanks to this analytical capability, at INFINITIA we support companies in the quality control of their raw materials, in the validation of suppliers, and in the resolution of incidents in finished products.

What does chemical analysis of metals consist of?

The chemical analysis of metals consists of determining the elemental composition of a metallic material and evaluating the presence of impurities or trace elements that may affect its behavior.

At INFINITIA, we carry out this process using optical emission and inductively coupled spectrometry techniques (ICP-OES, ICP-MS) to achieve maximum precision in the quantification of elements, as well as X-ray fluorescence (XRF) for non-destructive analysis and electron microscopy with EDX to study surfaces and detect localized contamination.

In addition, we integrate complementary methods such as thermal analysis (TGA, DSC) and electrochemical corrosion testing with a potentiostat, which allows us to correlate the chemical composition with the functional performance of the material. In this way, chemical analysis of metals not only reveals which elements are present, but also provides key information to anticipate the behavior of the material in service.

Benefits of chemical analysis of metals

Among the main benefits offered by this service at INFINITIA is the ability to ensure traceability and regulatory compliance of the metals used in a product. For example, in industrial projects, we have validated stainless steels intended for critical automotive parts, detecting deviations in composition that compromised their corrosion resistance.

Likewise, chemical analysis allows for the optimization of production processes, the identification of cross-contamination in manufacturing lines, and the verification of the homogeneity of batches of raw materials. Another key benefit is the reduction of costs associated with failures, since knowing the chemical composition with precision helps to avoid defects that could lead to claims or product recalls.

Thus, chemical analysis of metals is a strategic tool for decision-making in forensic engineering, material characterization, and approval testing.

Chemical analysis of metals at INFINITIA

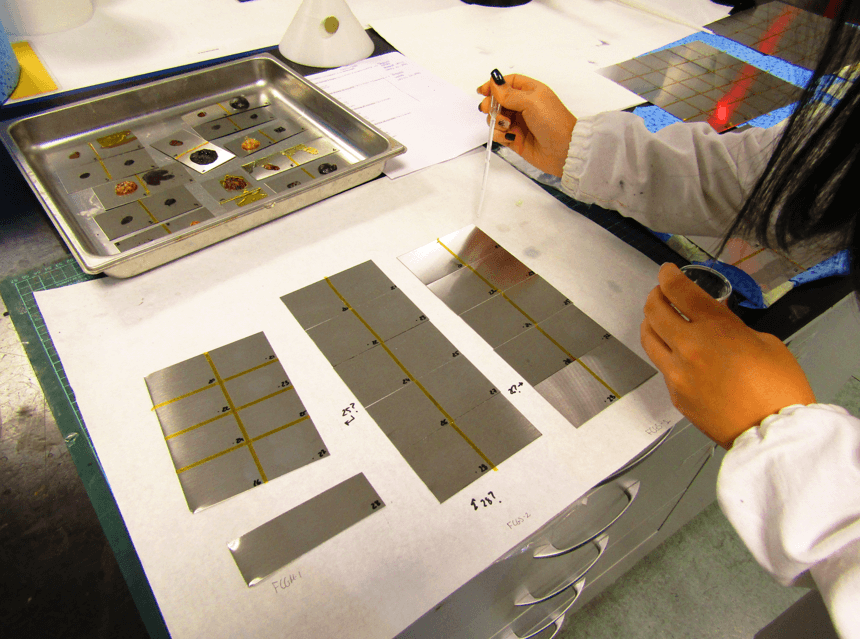

At INFINITIA, we develop this service from an applied and multidisciplinary perspective. Our chemical analysis and metallurgy laboratory is equipped with state-of-the-art instrumentation, and our specialists design each test according to the technical requirements of the client.

We adapt the analysis to different needs: from verifying the composition of an aluminum alloy used in aeronautical components to studying the corrosion resistance of steels exposed to corrosive atmospheres or validating galvanized materials used in high-performance applications.

In addition, thanks to our experience in forensic engineering, we not only identify the elements present, but also interpret the data to provide useful conclusions for failure investigation and process improvement.

With this combination of scientific rigor, advanced equipment, and applied vision, INFINITIA positions itself as a strategic partner in chemical analysis of metals for companies in any industrial sector.

Types of Chemical Analysis of Metals

At INFINITIA, we develop different chemical analyses of metals to determine their elemental composition, evaluate impurities, and validate the behavior of alloys used in multiple industrial sectors.

Our goal is to provide accurate information that allows for the optimization of material selection, ensures regulatory compliance, and anticipates possible failures in service.

Elemental analysis using ICP-OES and ICP-MS spectrometry

These analyses allow us to determine the elemental composition of metals and alloys with high precision. ICP-OES is used to quantify major and minor elements, while ICP-MS is ideal for detecting traces with very low detection limits.

At INFINITIA, we apply these techniques to ensure the quality of stainless steels, aluminum, and titanium in biomedical applications, guaranteeing that they meet the most demanding standards in the industry.

X-ray fluorescence (XRF)

XRF is a non-destructive technique that identifies and quantifies elements in solid samples without altering their structure. In our laboratory, we use it to verify the composition of production batches and ensure the homogeneity of copper, aluminum, or their alloys.

For example, we have used XRF in electrical component quality control projects, guaranteeing the purity of metal conductors.

Scanning electron microscopy (SEM) coupled with energy dispersive spectroscopy (EDX) allows us to analyze surfaces and detect impurities or phases in metallic materials.

At INFINITIA, we use it to study non-metallic inclusions in steels and surface contamination in machined parts. A typical case is the identification of oxides or sulfides in welds, which helps to correlate microstructural defects with functional failures.

Steel and Metal Profile Testing

We perform MUE (tensile, torsion, fatigue) tests, impact tests (Charpy), and corrosion resistance tests using salt spray or climate cycles.

At INFINITIA, we analyze structural profiles for facades subjected to extreme conditions, evaluating their durability and mechanical performance under thermal cycles.

Wood Testing

We perform tensile, compression, bending, and toughness tests, as well as moisture, density, and impact resistance analyses. We also develop aging and flammability tests.

For example, we collaborate with a manufacturer by performing customized tests to validate a new joint system.

Thermal analysis (TGA and DSC) in metals and metal compounds

Using thermogravimetry (TGA) and differential scanning calorimetry (DSC), we evaluate the thermal stability and energy transitions of metals and coatings.

These analyses allow us to anticipate the behavior of materials at high temperatures. In the automotive industry, for example, we have used DSC to validate the stability of protective coatings against intensive thermal cycles.

Corrosion testing and electrochemical studies

Corrosion resistance is a critical factor in the performance of metals. At INFINITIA, we use potentiostats and electrochemical techniques to simulate service conditions and measure the susceptibility of alloys to aggressive environments.

A recent case involved the evaluation of galvanized steels exposed to corrosive atmospheres, which allowed us to recommend the most suitable coating to extend the service life of the components.

Applications of Construction Material Testing

The chemical analysis of metals has direct applications in multiple industrial sectors. At INFINITIA, we apply it to validate raw materials, optimize processes, and guarantee the safety and functionality of end products.

Automotive Industry

Automotive manufacturers require metallic materials with high reliability. At INFINITIA, we perform chemical analyses of steels, aluminum, and metallic coatings to validate their composition and ensure their performance against fatigue, vibration, and corrosion.

- Validation of stainless steels in different batches.

- Evaluation of coatings using XRF and electrochemical testing.

- Purity control in aluminum components.

Aerospace and Energy

In these sectors, chemical analysis is key to guaranteeing the safety of materials in extreme conditions. At INFINITIA, we verify the composition of titanium and nickel alloys used in aeronautical components and systems.

- Detection of trace elements to evaluate their correlation with mechanical resistance at high temperatures.

- Evaluation of thermal stability of protective coatings against oxidation.

- Control of homogeneity in batches.

Food Industry and Metal Packaging

Metal packaging and coatings must comply with strict regulations. At INFINITIA, we perform chemical analyses and migration studies to ensure their safety.

- Evaluating how composition affects microwave heating.

- Corrosion resistance testing on cans.

- Verification of purity of internal coatings to prevent food contamination.

Medical Devices

In the medical sector, chemical composition determines biocompatibility and resistance to physiological corrosion. At INFINITIA, we analyze surgical steels, titanium, and alloys.

- Validation of alloys for orthopedic implants using ICP-MS.

- Study of passivation in stainless steels for instrumental components.

- Evaluation of migration in special alloys.

Construction and Infrastructure

Metallic materials in construction must withstand loads, moisture, and chemical agents. At INFINITIA, we perform chemical analyses to validate structural steels, reinforcements, and coatings.

- Composition control of reinforcing steels.

- Accelerated corrosion testing in corrosive environments.

- Verification of galvanizing to extend service life.

INFINITIA as a strategic partner in chemical analysis of metals: quality, innovation, and reliability

Chemical analysis of metals is a fundamental pillar for ensuring quality, safety, and reliability in today’s industrial processes.

At INFINITIA, we approach this service from a scientific and applied perspective, using cutting-edge techniques such as ICP-OES, ICP-MS, XRF, SEM-EDX, TGA, and DSC, as well as electrochemical corrosion testing.

This combination allows us not only to determine the elemental composition of metals, but also to anticipate their behavior under real service conditions and prevent failures that could compromise the safety or efficiency of products.

Relying on INFINITIA for chemical analysis of metals means having a specialized technical partner that combines expertise in forensic engineering, material characterization, and approval testing.

Our laboratory is equipped to adapt to the specific needs of each customer, whether to validate a batch of structural steels, ensure alloy compatibility, evaluate the corrosion resistance of a metallic coating, or analyze the purity of components intended for the automotive or aeronautics industries.

Current trends in this field point towards greater use of hybrid analytical techniques, capable of delivering real-time results and integrating into digitized manufacturing processes. Likewise, the growing demand for sustainability is driving the need for chemical analyses that enable the optimization of raw material use, reduce waste, and improve the traceability of recycled materials. In this context, INFINITIA is at the forefront, providing knowledge, rigor, and customized solutions to meet the challenges of the industry.

In short, choosing INFINITIA for chemical analysis of metals means ensuring exhaustive control over raw materials, strengthening competitiveness in the market, and minimizing risks associated with production.

Our commitment is to offer reliable results, high-value technical interpretations, and close support so that each company can transform the data obtained into strategic decisions that enhance its innovation and guarantee its long-term success.