Crystallographic Testing

Crystallographic testing is one of the most advanced tools for understanding the internal structure of solid materials such as metals, glass, ceramics, semi-crystalline polymers, and industrial coatings.

At INFINITIA, we apply these techniques to identify crystalline phases, determine lattice parameters, quantify crystallinity levels, and analyze structural defects that affect a product’s performance and durability.

Our industrial laboratory is staffed by highly qualified specialists and equipped with state-of-the-art X-ray diffraction (XRD), EBSD, and GIXRD equipment, enabling us to deliver reliable results that meet the most demanding technical standards.

In this way, crystallographic testing at INFINITIA becomes a key tool for forensic engineering, quality control, and innovation in leading industrial sectors.

What are crystallographic tests?

But what exactly are crystallographic tests? At INFINITIA, we explain this service as a set of techniques based on the interaction of radiation, usually X-rays or electrons, with the crystal lattice of a material.

The application of Bragg’s law allows diffraction patterns to be obtained which, through advanced analysis and refinement models such as the Rietveld method, provide detailed information on the phases present, crystallographic orientation, grain size, microdeformations, and texture of the material.

This critical data in research and development allows the structure to be correlated with mechanical, optical, electrical, or thermal properties, facilitating scientifically based technical decision-making.

Benefits of Crystallographic Testing in Industry

The benefits of crystallographic testing are numerous and decisive for the industry. At INFINITIA, we have demonstrated how structural characterization using XRD helps optimize manufacturing processes, select raw material suppliers, ensure the homogeneity of production batches, and anticipate failures associated with changes in microstructure.

For example, in the construction and architecture sector, crystallographic analysis of glass and ceramics allows for the validation of resistance to environmental agents and guarantees the durability of glazed elements.

In the automotive industry, the study of phases in steels or coatings is essential to ensure safety and performance.

Even in emerging sectors such as energy storage, crystallographic testing allows for in-situ monitoring of phase evolution in active battery materials, directly contributing to the development of more efficient and sustainable solutions.

Crystallographic Testing at INFINITIA

At INFINITIA, we carry out crystallographic testing with a comprehensive and applied approach. We have X-ray diffraction and scanning electron microscopy (SEM) equipment.

In addition, our multidisciplinary team combines expertise in forensic engineering, failure analysis, and materials characterization, allowing us not only to obtain structural data, but also to interpret it in the context of the actual behavior of the product.

This unique approach sets us apart, as we accompany each result with specific technical recommendations aimed at improving the design, quality, and competitiveness of our clients’ products.

Types of Crystallographic Tests

At INFINITIA, we develop different crystallographic tests to evaluate the internal structure of metallic, ceramic, glass, polymer, and composite materials. Our goal is to accurately determine the crystalline organization and phases present in each material, optimizing its application, functionality, and useful life in demanding industrial environments.

X-ray Diffraction (XRD/DRX)

These tests allow crystalline phases to be identified and their proportion in a sample to be quantified. Using Bragg’s Law and Rietveld refinement, unit cell parameters, crystallite size, residual stresses, and crystallographic texture are obtained.

At INFINITIA, we use XRD in automotive projects to validate special steels, ensuring their microstructure is suitable before they are used in various components.

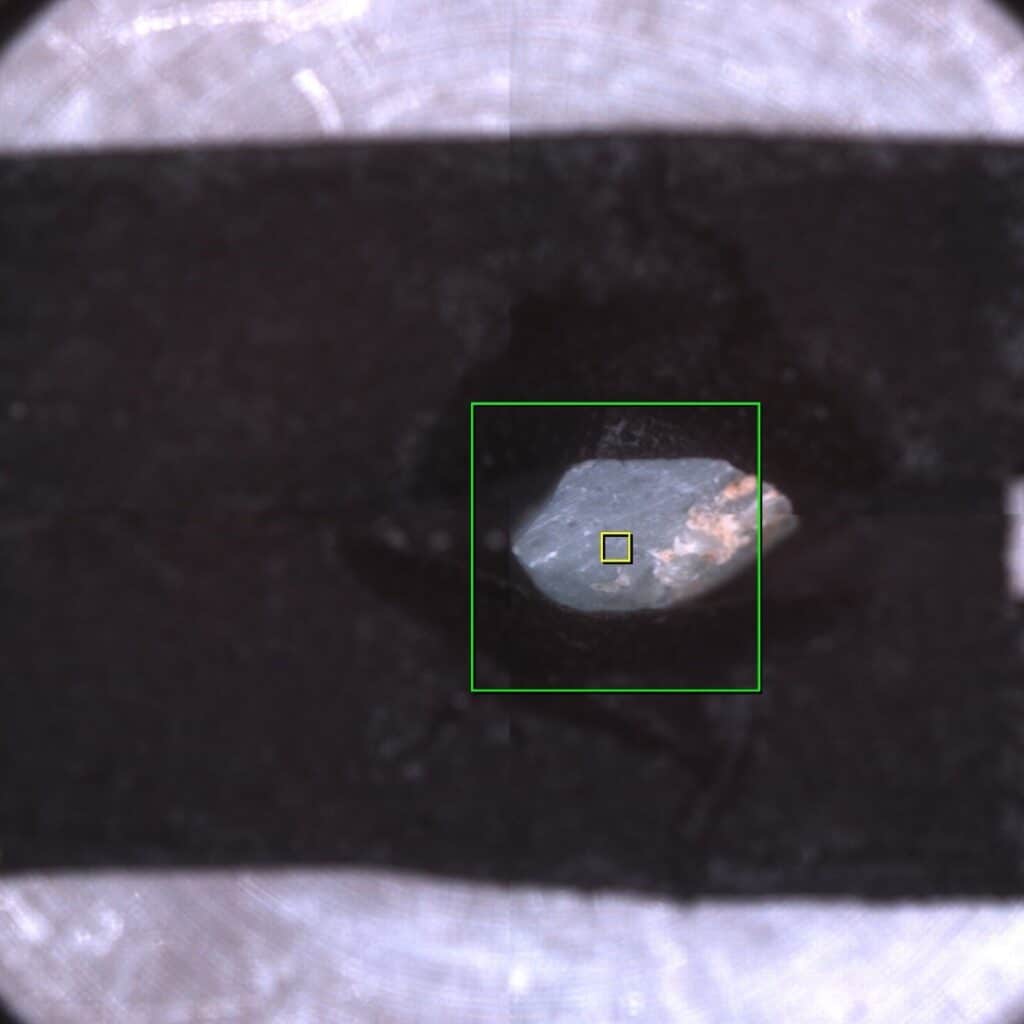

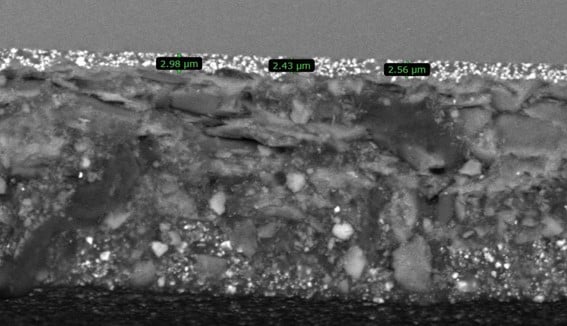

Grazing Incidence X-ray Diffraction (GIXRD)

GIXRD is applied to coatings and thin films, where conventional diffraction does not offer sufficient sensitivity. It allows the analysis of surface phases, stresses, and crystallinity in PVD, CVD, oxide, or protective coatings.

At INFINITIA, we have applied GIXRD to evaluate coatings on glass, ensuring their effectiveness and adhesion after accelerated aging cycles.

Using EBSD in scanning electron microscopy (SEM), maps of crystal orientation, grain size distribution, and grain boundary detection are obtained.

At INFINITIA, we use this technique to analyze plastic deformations in rolled metal sheets, which allows us to optimize forming processes in automotive and household appliance components.

Crystallinity Testing in Polymers and Composite Materials

Determining the degree of crystallinity is essential in semi-crystalline polymers and composite materials.

Using XRD, at INFINITIA we study the relationship between crystallinity and mechanical, thermal, or barrier properties.

Mineralogical and Ceramic Phase Analysis

In ceramic materials and glass, crystallographic testing allows us to identify phases, inclusions, and polymorphisms.

At INFINITIA, we analyze ceramic glazes to detect defects associated with unwanted phases, optimizing the quality of coatings and technical porcelain components.

Applications of Crystallographic Testing

Applied crystallography has a direct impact on multiple industrial sectors. At INFINITIA, we support companies in material validation, supplier selection, process optimization, and structural failure detection before they reach the market.

Automotive Industry

In the automotive industry, crystallographic testing allows for the validation of heat treatments in steels, the study of anti-corrosion coatings, and the assurance that components subjected to fatigue have the appropriate structure.

- Measurement of residual stresses in welds using XRD to ensure their integrity.

- Phase control in coatings.

- Optimization of high-strength steels.

Construction and Architecture

Crystallographic analysis of glass and ceramics ensures safety, transparency, and durability in facades, windows, and architectural coatings.

- Validation of laminated glass against moisture, radiation, and thermal shock.

- Study of crystalline phases in ceramics to ensure mechanical strength.

- Control of industrial enamels in decorative and functional coatings.

Energy and Electronics Industry

In electronic and energy systems, diffraction is key to studying active and dielectric materials.

- Phase analysis in lithium battery cathodes.

- Validation of insulating ceramics.

- Study of crystallization in epoxy encapsulants for electronics.

Pharmaceutical and Chemical Sector

In pharmaceuticals, crystallographic testing allows the study of polymorphisms that affect the bioavailability of active ingredients.

- Detection of different crystalline forms in bioactive compounds.

- Control of structural stability in excipients and additives.

- Validation of crystalline phases in industrial salts and minerals.

Food and Packaging

In food packaging, crystallinity determines mechanical strength, thermal stability, and barrier performance.

- Quantification of crystallinity in films.

- Evaluation of protective coatings in packaging.

- Control of microstructure in plastics.

Crystallographic testing with INFINITIA

Crystallographic testing is an essential tool for understanding the structural organization of complex materials in detail and, thereby, anticipating their behavior in real applications.

Using classic techniques such as X-ray diffraction (XRD/DRX) and advanced methodologies such as GIXRD for coatings or EBSD for crystalline orientation maps, it is possible to obtain key information on the phases present, residual stresses, crystalline textures, and degree of crystallinity in different families of materials.

At INFINITIA, we put these techniques at the service of industry with an applied and multidisciplinary approach. We do not limit ourselves to obtaining diffraction patterns, but rather integrate them with our experience in forensic engineering, materials characterization, and failure analysis, offering interpretations that translate into concrete technical decisions. Thanks to this vision, we accompany our clients in the optimization of raw materials, process validation, supplier selection, and the development of innovative products.

The importance of crystallographic testing will continue to grow in an increasingly regulated and competitive industrial environment. Sectors such as automotive, construction, energy, and pharmaceuticals already demand this type of testing to ensure the reliability of their materials and compliance with international regulations. In the future, trends in in-situ and operating testing, capable of monitoring phase transformations in real time, will open up new possibilities for innovation in advanced materials such as those used in lithium batteries, functional coatings, and biomedical devices.

Relying on INFINITIA for crystallographic testing means having a strategic partner capable of combining analytical precision with applied vision. Our commitment is to provide reliable results, useful interpretations, and practical recommendations that enable companies to improve their quality, competitiveness, and sustainability.

If your goal is to advance the structural knowledge of your materials and transform it into a competitive advantage, INFINITIA is the ally you need.