Material Characterisation

Material characterisation is a key process in industry to ensure the quality, functionality, and reliability of products throughout their entire life cycle.

At INFINITIA Industrial Consulting, we offer a comprehensive material characterisation service aimed at precisely understanding the physical, chemical, and mechanical behaviour of any substance or component. This knowledge is essential for making strategic decisions in the design, development, manufacturing, and validation of industrial products.

Our material inspection protocols complement these analyses, enabling a complete evaluation from the reception of raw materials to the final validation of the product.

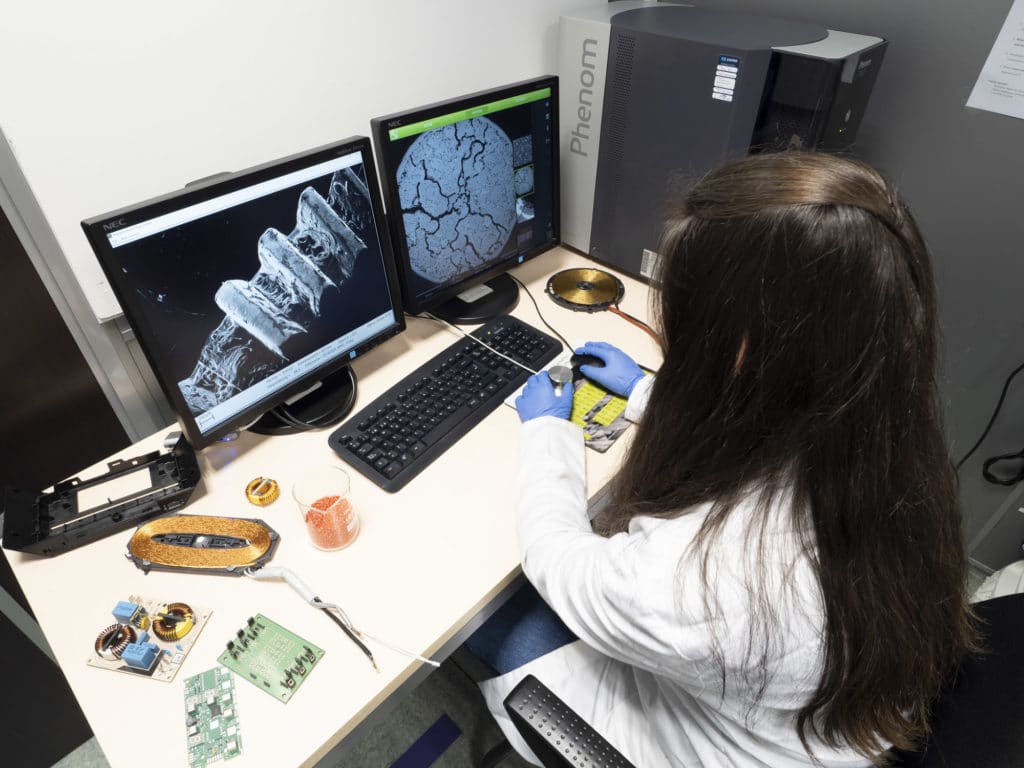

At INFINITIA’s industrial laboratory, we have a team of material specialists and cutting-edge technology to carry out these analyses with the highest precision and technical rigor.

What does material characterisation involve?

Material characterisation involves studying the structural, morphological, and functional properties of a substance to determine its composition, resistance, durability, behaviour under external stresses, and potential industrial applications.

Using advanced techniques such as spectroscopy, microscopy, thermal analysis, or mechanical and corrosion testing, at INFINITIA we analyse metallic materials as well as polymers, ceramics, composites, and coatings. Material inspection through these techniques allows us to establish relationships between a material’s internal structure and its performance under real-world conditions, predicting its behaviour and reliability.

Benefits of Material Characterisation

One of the main benefits of material characterisation is its ability to optimise the production process from the earliest stages. At INFINITIA, we help our clients select the best raw materials, validate suppliers, prevent potential failures due to fatigue or corrosion, improve design efficiency, and extend the service life of products.

For example, through thermal and mechanical testing, we have optimised plastic formulations to achieve stronger materials or selected the most suitable metal alloys for components exposed to harsh environments.

These data-driven decisions have a direct impact on the competitiveness of the final product.

Material Characterisation and Inspection at INFINITIA

At INFINITIA, we approach each material characterisation project with a multidisciplinary focus, combining knowledge in forensic engineering, material science, and sector-specific technical regulations. Our material inspection protocols are seamlessly integrated with analytical testing to provide a comprehensive evaluation.

Our laboratory is equipped with the latest technology to perform both destructive and non-destructive tests, covering all analysis phases, including sample preparation.

Whether it’s the characterisation of plastics, metals, composites, or innovative materials, at INFINITIA we provide a technical and consultative service tailored to the specific requirements of each client and industrial application.

Types of Material Characterisation Tests

At INFINITIA, we conduct various characterisation tests to assess the physical-chemical, thermal, mechanical, and structural properties of materials used in industrial products. Our goal is to precisely understand the behaviour of each material, optimising its application, functionality, and lifespan.

Composition and Chemical Structure Tests

These tests identify the elements and compounds in a sample and how they are arranged at the molecular level. Techniques include infrared spectroscopy (FTIR), atomic absorption spectroscopy (AAS), X-ray fluorescence (XRF), and nuclear magnetic resonance (NMR).

These tests are essential for verifying the composition of raw materials, identifying cross-contamination, and validating compound purity. For example, at INFINITIA we have used FTIR to identify unknown additives in technical polymers used in automotive components.

Microscopy and Morphological Analysis

Microscopy tests enable the observation of microstructures, detection of surface defects, and analysis of internal phases in metals, ceramics, or composites.

We use optical microscopy, scanning electron microscopy (SEM), and atomic force microscopy (AFM) to generate detailed images. For example, in a project for the electronics industry, SEM was used to identify microcracks in critical solder joints, optimising production parameters to reduce failures.

These tests evaluate a material’s behaviour under stress such as tension, compression, torsion, or fatigue. At INFINITIA, we carry out hardness tests, elastic modulus measurements, and impact resistance testing in accordance with international standards (ISO, ASTM).

A common case is the validation of the resistance of plastic casings for certain components, where we conduct drop and impact tests to assess their durability under real use conditions.

Thermal Testing

Thermal analyses determine how a material behaves under temperature changes. We use techniques such as DSC and TGA to analyse glass transitions, thermal stability, or mass loss.

For instance, in the development of a new insulation material, we applied differential scanning calorimetry to ensure that the polymer retained its properties under operational conditions.

These tests simulate extreme conditions to predict a material’s durability against corrosion, humidity, or ageing. We use methods such as salt spray testing, climate chambers, electrochemical testing, and various accelerated tests to reproduce in weeks what would normally occur over years.

In one case for components, several metallic coatings were compared after 500 hours of salt spray exposure to select the best option for oxidation resistance.

Migration and Purity Tests (Chromatography)

Using gas (GC) and liquid chromatography (HPLC), we analyse residues, migrations, and volatile compounds. These tests are crucial for materials in contact with food or used in medical devices.

At INFINITIA, we’ve used HPLC to measure plasticiser migration in food packaging films, ensuring compliance with European legislation (EU 10/2011).

Applications of Material Characterisation

Automotive Industry

In automotive applications, materials must withstand vibrations, mechanical loads, and extreme climates. Characterisation enables the selection of lightweight, durable, and resistant solutions for structural components, plastic casings, metallic coatings, or fatigue-prone parts.

- Validation of plastic casings under thermal cycles and impacts to ensure long-term integrity.

- Comparison of metallic coatings via salt spray testing to select the most corrosion-resistant option.

- Fatigue evaluation of structural parts through tensile and cyclic bending tests.

Food & Packaging Industry

Packaging materials must ensure food safety and preserve product properties. Characterisation validates thermal resistance, barrier behaviour, and potential substance migration, meeting European and sector-specific regulations.

- Plasticiser migration testing in food packaging using chromatography (HPLC and GC).

- Thermal analysis of films to validate resistance to pasteurisation processes.

- Measurement of barrier properties against moisture and oxygen to improve food preservation.

Medical Devices

Medical materials must withstand sterilisation processes, maintain dimensional stability, and not release toxic substances. Characterisation ensures the safety, functionality, and lifespan of polymers, coatings, and implantable or disposable parts.

- Thermal studies to verify polymer stability after steam or gas sterilisation.

- Structural characterisation of polymers used in temporary implants through microscopy and mechanical testing.

- Detection of chemical residues in devices via liquid chromatography.

Energy & Electronics Sector

In electronic and energy systems, materials must offer thermal stability, dielectric resistance, and predictable behaviour under load cycles. Characterisation ensures reliability in encapsulants, insulators, and components for power electronics or e-mobility.

- Analysis of ceramics used in batteries and power systems.

- Thermal evaluation of electronic circuit encapsulants using DSC and TGA.

- Quality control of epoxy resins used in converters and transformers.

Construction Industry

Construction materials must retain structural integrity under moisture, loads, abrasion, and chemical agents. Characterisation helps predict long-term performance and validate solutions in line with technical regulations and environmental demands.

- Compression tests on reinforced concrete as per technical standards.

- Accelerated ageing tests on façade panels to assess moisture and UV resistance.

- Surface wear measurement on industrial floors through mechanical tests.

Technical Textiles & Functionalised Materials

Technical textiles and functional surfaces must retain properties like fire resistance, antimicrobial effect, or thermal comfort. At INFINITIA, we characterise these materials to validate their effectiveness and durability in real-world conditions.

- Tear and fire resistance testing in technical fabrics for workwear and transport.

- Analysis of antimicrobial coatings on textiles via electron microscopy.

- Thermal studies of fabrics with temperature-regulating properties to enhance comfort.

Why Choose INFINITIA for Material Characterisation

Material characterisation is an essential tool for ensuring the reliability, functionality, and efficiency of industrial products in demanding sectors. It provides in-depth insight into the physical, chemical, mechanical, and thermal properties of materials, identifies defects, validates suppliers, and anticipates potential failure modes.

From raw material selection to manufacturing process improvement, characterisation testing provides objective data that reduces technical uncertainty and supports strategic product development decisions.

At INFINITIA, we combine state-of-the-art equipment, specialised personnel, and scientific methodologies tailored to each case. Our multidisciplinary approach allows us to tackle complex projects with rigour—whether validating new materials, solving quality issues, or adapting components to specific regulations. We work with both large manufacturers and industrial SMEs, delivering tailored technical solutions that make a direct impact on our clients’ competitiveness.

Contact US

For a PRIORITY RESPONSE, please contact us through the following form.