Analysis of heat treatments for metals

The analysis of heat treatments of metals is a key process for verifying whether a metal component has been correctly subjected to processes such as hardening, tempering, annealing, or thermochemical treatments.

At INFINITIA, we evaluate how these treatments modify the properties and microstructure of the material, ensuring that the desired mechanical, structural and functionality objectives are achieved. Our heat treatment laboratory has specialists in characterization of metallic materials and advanced diagnostic techniques that allow us to identify deviations, validate the quality of the thermal process applied and optimize the treatment cycles.

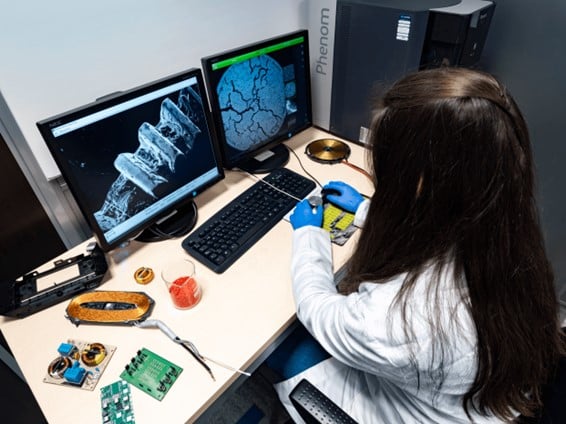

At the INFINITIA industrial laboratory, we work with state-of-the-art technologies to characterize heat treatments. We apply techniques such as scanning electron microscopy (SEM), hardness testing (Vickers, Rockwell, Brinell), metallographic analysis, optical emission spectrometry (OES), cross-sectional metallographic cutting or EDX analysis, among others.

This allows us to obtain a comprehensive view of the behavior of the metal after treatment and verify both its effectiveness and uniformity, as well as any possible alterations to the base material.

What does the analysis of heat treatment of metals and steel consist of?

The characterization of heat treatments consists of studying how a metal has evolved after being subjected to a controlled thermal process.

At INFINITIA, we evaluate the microstructure of the material, measure its hardness and mechanical strength, and determine whether the appropriate thermal conditions have been achieved in terms of temperature and cooling rate. This analysis is essential for industries where the time and cooling rate are critical factors. time, and cooling rate. This analysis is essential for industries where the mechanical behavior of the material is directly related to its performance in service.

Depending on the type of heat treatment applied, changes in the structure of the material can be expected, such as the transition from an austenitic phase to a martensitic phase in tempered steels, or the homogenization of the structure through annealing. At INFINITIA, we study these changes with rigor, combining microscopic observations and localized chemical analyses to ensure a complete and accurate diagnosis.

Benefits of metal heat treating analysis

One of the main benefits of heat treatment analysis is to ensure that the treated component meets the established functional and regulatory requirements. This type of analysis makes it possible, for example, to detect whether a part has not been properly tempered or whether there is an area with insufficient hardness due to a lack of thermal penetration.

At INFINITIA, we have helped clients in the automotive sector to diagnose failures in tempered components, and companies in the machining sector to optimize the thermal cycles of critical parts through metallographic validation and post-treatment hardness analysis.

In addition, these techniques make it possible to identify undesirable alterations in the base material, process errors, overheating or inadequate cooling that could compromise the long-term integrity of the component.

This knowledge not only prevents premature failures, but also allows for design optimization to reduce component fragility, as well as the manufacturing process from the early stages of the project.

Analysis of heat treatments for metal material and microstructure at INFINITIA

At INFINITIA, we carry out the analysis of heat treatments in metals by combining experience, advanced technologies, and a rigorous approach. Our technicians apply methodologies specific to forensic materials engineering, using equipment such as optical spectrometers, SEM microscopes with EDX, heat treatment furnaces and mechanical testing machines.

Our laboratory has the necessary capabilities to evaluate complex microstructures after heating and cooling, and correlate them with heating and cooling process parameters. In addition, we can perform comparative studies between treated and untreated samples, detect errors in the application of the treatment, validate the effectiveness of suppliers, and perform post-failure diagnostics. All this with the aim of ensuring that each heat-treated component is safe, reliable, and functional throughout its useful life.

Types of Heat Treatment Analysis in Metals and alloys

At INFINITIA, we develop different types of analyses to characterize how heat treatments affect the behavior of metallic materials. Our goal is to verify that these treatments have produced the desired changes in the microstructure and mechanical properties, as well as to anticipate possible deviations or critical defects that could compromise the functionality of the componentmicrostructure and mechanical properties, as well as to anticipate possible deviations or critical defects that could compromise the functionality of the component. These tests are key to guaranteeing the quality of the final product and ensuring the traceability of the thermal process applied.

Metallographic analysis

Metallographic analysis is a fundamental technique for studying the effects of heat treatment at the microstructural level. It allows the identification of the phases present (such as ferrite, pearlite, martensite, or bainite), as well as evaluate grain morphology and the existence of defects such as porosity, segregation, or internal cracks.

This type of analysis is performed on samples prepared by cutting, embedding, polishing, and selective chemical etching, which facilitates visualization using optical microscopy.

At INFINITIA, we use this technique to verify the effectiveness of the tempering, the quality of the annealing, and the distribution of phases after a combined treatment. Thanks to this technique, we can confirm the desired thermal transformation and diagnose errors such as overheating or lack of thermal penetration.

Optical and electron microscopy (SEM) with EDX analysis

Optical microscopy allows for a general analysis of the structure, but when a greater level of detail is required or specific areas of the material need to be studied, we use scanning electron microscopy (SEM).

This technique offers very high resolution, ideal for observing microcracks, fine-grained structures, and complex surface transformations. We combine SEM with energy dispersive X-ray analysis (EDX), which allows us to identify the specific chemical composition of microzones affected by the treatment.

At INFINITIA we use this methodology in situations where it is necessary to confirm the presence of carbides, alloying segregation or areas with surface contamination after tempering or thermochemical treatment.

Hardness is one of the parameters most sensitive to heat treatments and a direct way of assessing their effectiveness. At INFINITIA, we perform hardness profiles on cross-sections to check the depth and uniformity of the treatment.

The Vickers technique is used for small areas or thin coatings, while Rockwell and Brinell are applied to larger parts or functional surfaces. This information is key to verifying the effectiveness of the hardening, the degree of tempering, or the correct execution of a carburizing process.

Detecting areas with insufficient or excessive hardness helps prevent problems of premature wear, fracture, or loss of functionality in actual use.

Tensile and mechanical strength tests

Heat treatments modify the strength, ductility, and toughness of materials after treatment. Therefore, tensile tests are essential to confirm that the treatment has produced the expected properties. This type of test determines the yield strength, ultimate strength, elongation and reduction in area of the treated material.

At INFINITIA we carry out these tests in accordance with standards (ASTM, ISO) to validate processes such as normalization, annealing, or tempering in structural parts.

These data allow the microstructural state to be correlated with the mechanical behavior, optimizing the design and manufacturing process.

Metallographic cross-section and thickness control

In surface heat treatments, such as nitriding, carburizing, or induction hardening, it is essential to know the depth achieved.

To do this, we perform cross-sectional metallographic cuts that allow us to accurately measure the effective thickness of the treatment. This information is essential for validating the uniformity of the process and ensuring that the part meets the requirements for wear resistance or surface fatigue.

At INFINITIA, we apply this technique both for quality control in production series and in forensic analysis of failures where insufficient thermal penetration is suspected.

Optical emission spectrometry (OES)

During heat treatment, especially at high temperatures, there may be a loss of alloying elements or the incorporation of contaminants by diffusion.

Optical emission spectrometry (OES) allows for highly accurate analysis of the chemical composition of the material after the process, comparing it with that of the original base material. This technique is key to verifying that the heat treatment has not caused critical alterations that could compromise the mechanical performance or corrosion resistance.

At INFINITIA we use the OES both in process validations and in failure analysis, where it is necessary to determine whether there has been a loss of chromium, molybdenum or other strategic elements.

Applications of Heat Treatment Analysis

The characterization of heat treatments in metals is an indispensable tool for validating the quality of thermal processes in different industrial sectors. Each industry has specific requirements in terms of mechanical properties, microstructural properties, or durability that must be verified after treatment.

At INFINITIA, we apply advanced techniques of metallographic analysis, hardness testing, tensile testing, optical emission spectrometry (OES), and electron microscopy (SEM/EDX) to ensure that heat-treated materials meet the required functional, regulatory, and safety standards. regulatory and safety standards.

Our experience in forensic engineering, industrial process validation, and quality control allows us to tailor our analysis to each client’s specific requirements, providing key information for technical decision-making, treatment optimization, and failure prevention in service.

Automotive Industry: Heat treatment of metals for hardened steel and high durability

In the automotive industry, heat treatments are critical to ensuring the hardness, toughness, wear resistance, and dimensional stability of components subjected to mechanical loads. toughness, wear resistance, and dimensional stability of components subjected to high mechanical loads and repetitive cycles after treatment. Parts such as gears, camshafts, valves, drive shafts, or suspension components depend directly on the correct execution of hardening, tempering, or carburizing to achieve their expected service life.

At INFINITIA, we validate these treatments using a combined approach of metallographic analysis, hardness profiles, and the study of defects associated with poorly executed thermal processes.

- Verification of the hardening depth in drive shafts using cross-sectioning and Vickers microhardness testing.

- Diagnosis of incomplete tempering, over-tempering, or excessive tempering in series affected by premature failures.

- Comparison of alternative heat treatments to optimize costs without compromising component durability.

- Technical support for complaints to heat treatment suppliers.

Industrial Machinery and Boiler Making: annealing metal heat treatment process for structural stabilization

In heavy machinery, boiler making, and welded structures, heat treatments such as annealing and normalizing are essential for stabilizing the microstructure, reducing internal stresses, and ensuring uniform mechanical behavior. These processes are particularly critical in large components subjected to thermal stresses, cyclic loads, or multiple welds.

At INFINITIA, we evaluate the actual effectiveness of these treatments, beyond their correct nominal execution.

- Validation of annealing and normalizing treatments through grain size analysis and post-treatment tensile testing.

- Comparative evaluation between treated and untreated areas to confirm the elimination of residual stresses.

- Control of thickness and uniformity in hardened coatings applied after heat treatments.

- Identification of risks of cracking or deformation in service.

Aerospace sector: heat treatment methods for metals in critical alloys

In the aerospace sector, heat treatments applied to nickel superalloys (Inconel), titanium, or precipitation-hardened stainless steels require thorough validation due to the structural criticality of the components. Any microstructural deviation can compromise the safety of the entire system.

At INFINITIA, we perform advanced analyses aimed at confirming the correct sequence and effectiveness of these treatments.

- Study of fine grain, phase distribution, and absence of pores using scanning electron microscopy (SEM) and EDX analysis.

- Validation of multiple or sequential heat treatments.

- Evaluation of microstructural homogeneity in critical parts.

- Ensuring structural integrity in components subjected to extreme temperature and load conditions.

Tool and Die Manufacturing: Heat treatment of steel for controlled hardness

Cutting tools, injection molds, dies, and industrial tooling require heat treatments that provide high surface hardness without introducing brittleness, microcracks, or excessive internal stresses. An improperly adjusted treatment can cause premature breakage or accelerated wear.

At INFINITIA, we analyze the actual balance between hardness and toughness achieved after heat treatment.

- Measurement of hardness profiles at different depths to validate tempering and annealing.

- Detection of superficial or subsurface microcracks using SEM.

- Diagnosis of faults associated with overheating, incorrect maintenance times, or inadequate cooling.

- Technical support for optimizing thermal cycles in critical tools.

Energy and Petrochemicals: Benefits of Heat Treatment of Metals for Mechanical Strength and Corrosion Resistance

In the energy and petrochemical sectors, heat treatments ensure both mechanical strength and corrosion resistance in components subjected to high pressures, elevated temperatures, and aggressive environments. Boilers, exchangers, valves, and pipes depend on a stable and well-controlled microstructure.

At INFINITIA, we validate these treatments to ensure compliance with regulatory requirements and long-term reliability.

- Analysis of the microstructural evolution after normalizing, tempering, or annealing.

- Verification of the retention of critical alloying elements (Cr, Mo, Ni) using OES spectrometry.

- Tensile, hardness, and metallography tests to confirm mechanical properties after heating and cooling.

- Risk assessment of degradation under extreme service conditions.

Capital Goods and General Mechanical Manufacturing: quality control of metal heat treatment

Many manufacturers of machined parts outsource heat treatments and require independent external control to confirm compliance with technical specifications, drawings, and regulations. At INFINITIA, we act as a reference laboratory to validate these processes.

- Metallographic analysis, hardness testing, and OES spectrometry as an external quality control service.

- Verification of compliance with technical drawings and applicable standards, with detailed technical reports.

- Support in the approval of new heat treatment suppliers through comparative analyses between OK/NOK samples.

- Diagnosis of deviations before they lead to field failures.

Effect of heat, quality control and reliability in heat treatment processes for steel and metals with INFINITIA

The analysis of heat treatments in metals is an essential process for ensuring the reliability, functionality, and durability of metal components used in industry. Validating that the processes of hardening, tempering, annealing or thermochemical treatments have been carried out correctly allows structural failures to be prevented, optimize production parameters and improve the performance of the final products. In this context, having a specialized laboratory such as INFINITIA offers a clear competitive advantage.

At INFINITIA, we approach thermal analysis with a comprehensive and scientific approach, supported by techniques such as metallographic analysis, optical emission spectrometry (OES), scanning electron microscopy (SEM), mechanical testing and microstructure characterization. Our technical team rigorously evaluates both the internal structure of the material and its behavior under real mechanical stresses, thus ensuring compliance with the most demanding technical specifications.

In addition, the heat treatment analysis service we offer is key in supplier approval processes, quality control, non-conformity resolution, and failure diagnosis through forensic engineering. Thanks to our multi-sector experience, we support companies in the automotive, aeronautics, industrial machinery, energy, and boiler sectors. aeronautics, industrial machinery, energy and heavy boiler making companies make strategic decisions based on reliable and reproducible data.

In an increasingly competitive and regulatory industrial environment, anticipating problems is vital. That is why at INFINITIA we help our clients not only to validate what has already been done, but also to improve what is yet to come. Choosing our heat treatment analysis services means choosing quality, efficiency, and technical innovation, backed by a team of experts in industrial materials and processes.