Define product requirements and specifications

At INFINITIA Industrial Consulting, we understand that the precise definition of requirements and product specifications is a critical phase in industrial product development.

This service, offered by our experts, is based on a technical and meticulous approach to determine the characteristics, functionalities, specifications and restrictions that a product must meet in order to be successful.

From our industrial laboratory and our specialised team, we offer consulting services to define the minimum criteria, characteristics and functionalities of the final products required in each industry.

What is the definition of product requirements and specifications?

The definition of requirements is the process by which the customer’s needs and expectations regarding the final product are established.

This process is complemented by the technical specification, which details how these requirements must be met in technical, regulatory and performance terms.

At INFINITIA, we carry out a comprehensive study of each project, helping our clients to identify the strategic objectives and key needs of the end user, thus ensuring that products are not only viable but also effective and aligned with market expectations.

Benefits of defining requirements and specifications

Having a well-defined process for establishing product requirements provides clear guidance throughout the product development lifecycle.

At INFINITIA, we not only define these requirements, but also align all team members with clear expectations and well-structured objectives. Thanks to our experience in the field of forensic engineering, we optimise product costs, durability and quality, reducing risks and ensuring compliance with international standards.

Specification definition at INFINITIA

At INFINITIA, we pride ourselves on offering a comprehensive and personalised approach to product specification definition. This includes clearly and technically establishing the product’s appearance, behaviour and the conditions under which it must perform.

To do this, we analyse the actual use and needs of the user, followed by a study of the product’s regulatory and operating environment.

Following this study, INFINITIA translates this into specific technical specifications, prioritising functional and safety criteria.

At INFINITIA, we are experts in defining product requirements with clear and measurable objectives, which minimise unforeseen events and ensure the durability, safety and perceived value of the product by the customer.

Types of tests to define product requirements and specifications

At INFINITIA Industrial Consulting, we review regulations and carry out a wide range of tests to precisely define product requirements and specifications, ensuring that both individual components and the final product meet performance and safety expectations and comply with applicable regulations in various industries.

To do this, we carry out different types of tests:

Product functional evaluation tests

These tests allow us to validate whether a product meets the functionality criteria necessary for use in real conditions.

To do this, we carry out a precise study of the product’s use case and simulate tests under real or accelerated conditions of use.

For example, at INFINITIA we carry out a functional analysis of components to evaluate the optimal time and temperature range. To do this, we design a customised set-up that allows us to continuously measure their performance under real and accelerated conditions, thus optimising the design and functionality of the product.

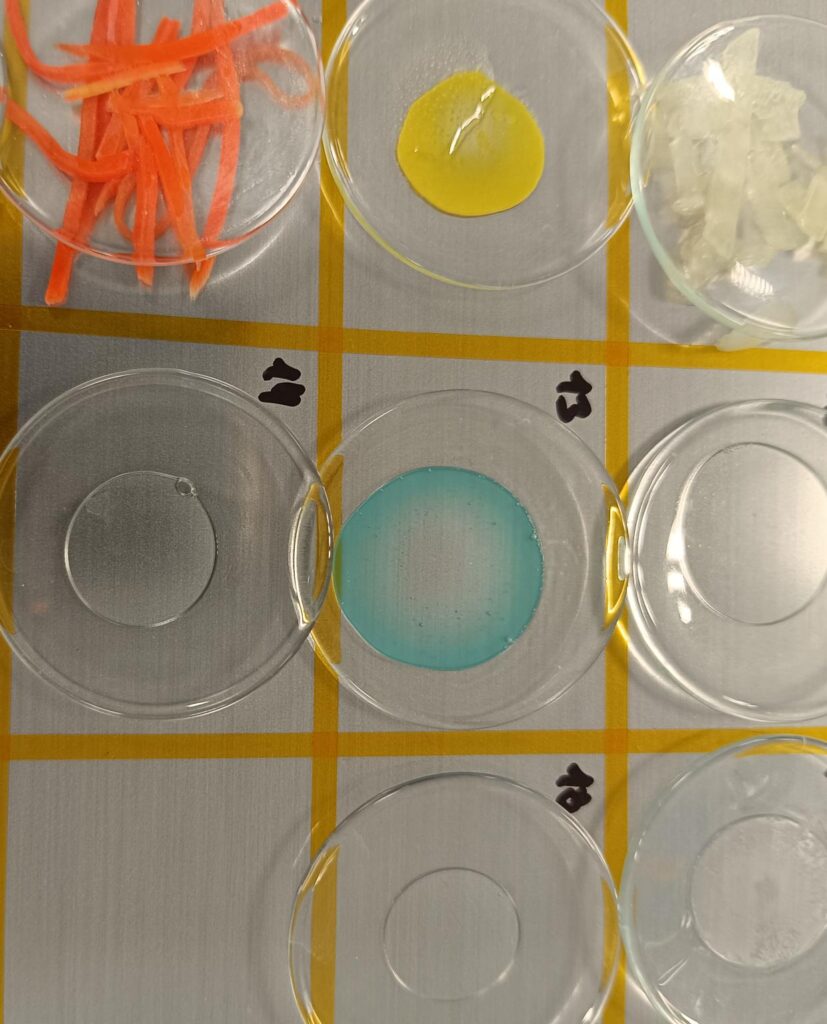

Chemical composition and property tests

These tests allow us to determine whether the final products meet the composition criteria once they have been manufactured.

At INFINTIA, we are able to determine the concentration of harmful substances that the product may emit after a period of use.

An example of this was when we carried out chemical composition tests using GC-MS to verify compliance with TLV values, ensuring safety in use. This guarantees that no hazardous substances are released at levels that are harmful to health.

Mechanical and resistance tests

Mechanical resistance is essential to ensure that a product can withstand the mechanical stress it will be subjected to during its life cycle. We carry out tensile, compression and torsion tests in accordance with international standards such as ISO and ASTM.

An example of this was a case in which we used compression testing to evaluate the stability of construction components, which enabled them to withstand the pressure applied without suffering structural damage.

Thermal behaviour, durability and accelerated ageing tests

We determine how products respond to variations in temperature and humidity under real-life conditions through accelerated ageing tests.

This makes it possible to simulate the passage of time, evaluate their useful life and verify their functionality in a reduced test period.

At INFINITIA, we have extensive experience in this type of testing, enabling us to offer accurate analyses and solutions tailored to the needs of each product.

Biocompatibility and safety testing

These tests evaluate the product’s resistance to microorganisms and ensure that it generates an acceptable biological response during the expected time and mode of contact.

An example of this is a project in which INFINITIA carried out a biocompatibility study to define the material, manufacturing process and sterilisation of implants, establishing the minimum tests required to guarantee their safety.

Applications of product requirements and specifications

The precise definition of product requirements and specifications is crucial for various industries. At INFINITIA, we work with different sectors to ensure that the products developed comply with regulations, technical standards and user expectations. Below are some of the most relevant applications of this service.

Chemical and manufacturing industry

In the chemical industry, it is essential to establish the requirements of synthesised and/or manufactured products for their final application. A good example of this is:

- The performance of thermal conductivity tests on polymers, which provided the information necessary to select the most suitable material.

- The use of scanning electron microscopy (SEM) to inspect screws and define product specifications.

Certification and approval testing

- In certification processes, it is necessary to comply with a series of pre-established requirements that allow the final product to be validated and optimised. At INFINITIA, we have experience in this field, as demonstrated by our work in various cases: In the REACH registration, where we help our clients identify and comply with the requirements necessary to register their products properly.

- In ASME certification, where we adapt and carry out the required analyses to ensure that the final products of a manufacturing plant comply correctly with the regulations.

Automotive industry

In the automotive industry, products must meet functionality and quality requirements. At INFINITIA, we have extensive experience:

- We carry out impact tests to identify the most resistant product, thus guaranteeing the integrity of the casings.

- We apply reverse engineering to define specifications and select products that meet the requirements, or to detect those that are out of tolerance.

Medical and healthcare industry

The medical and healthcare industry is one of the most demanding sectors. At INFINITIA, we work with our clients to establish quality requirements and the minimum testing necessary to optimise results and reduce costs. We perform biocompatibility tests to certify products and ensure they comply with safety standards.

- We define functional requirements through simulated use tests, evaluating the behaviour of drug delivery devices at different temperatures.

Why choose an expert approach to defining product requirements and specifications?

At INFINITIA, we adapt the definition of requirements and specifications to the particularities of each sector, ensuring safer, more efficient products that are aligned with the most demanding technical and regulatory standards. Our approach combines regulatory knowledge, practical experience in multiple industrial sectors and the use of advanced analysis and simulation tools.

Having an expert team like INFINITIA allows you to anticipate potential quality deviations, optimise design from early stages and reduce costs associated with redesigns, non-conformities or market incidents. In addition, thanks to our ability to link product functional requirements with real validation tests, we help companies make informed decisions about materials, processes and suppliers.

One of our main strengths is integrating this process with other key technical services. From forensic engineering, we provide an analytical vision aimed at identifying product failure modes and critical points. Through approval testing, we validate that each specification translates into reliable, compliant performance. Through material characterisation, we confirm that the selected materials meet the necessary properties for each application and service environment.

This expert approach not only improves the technical robustness of the final product, but also reinforces the traceability and documentation required for approval, certification or audit processes.

In short, choosing INFINITIA means integrating technical knowledge with the strategic vision necessary to ensure the industrial success of each project, anticipating challenges and consolidating quality from the very beginning of development.