Initial fault diagnosis

Root cause failure diagnosis is an essential service for any industrial company seeking to improve the reliability of its processes, products and components.

At INFINITIA Industrial Consulting, we use this service to detect, analyze and resolve functional failures that affect the quality, safety or performance of systems. Through a combination of advanced techniques and expert knowledge, we help our clients identify precisely what is going wrong, why and how to prevent it from happening again.

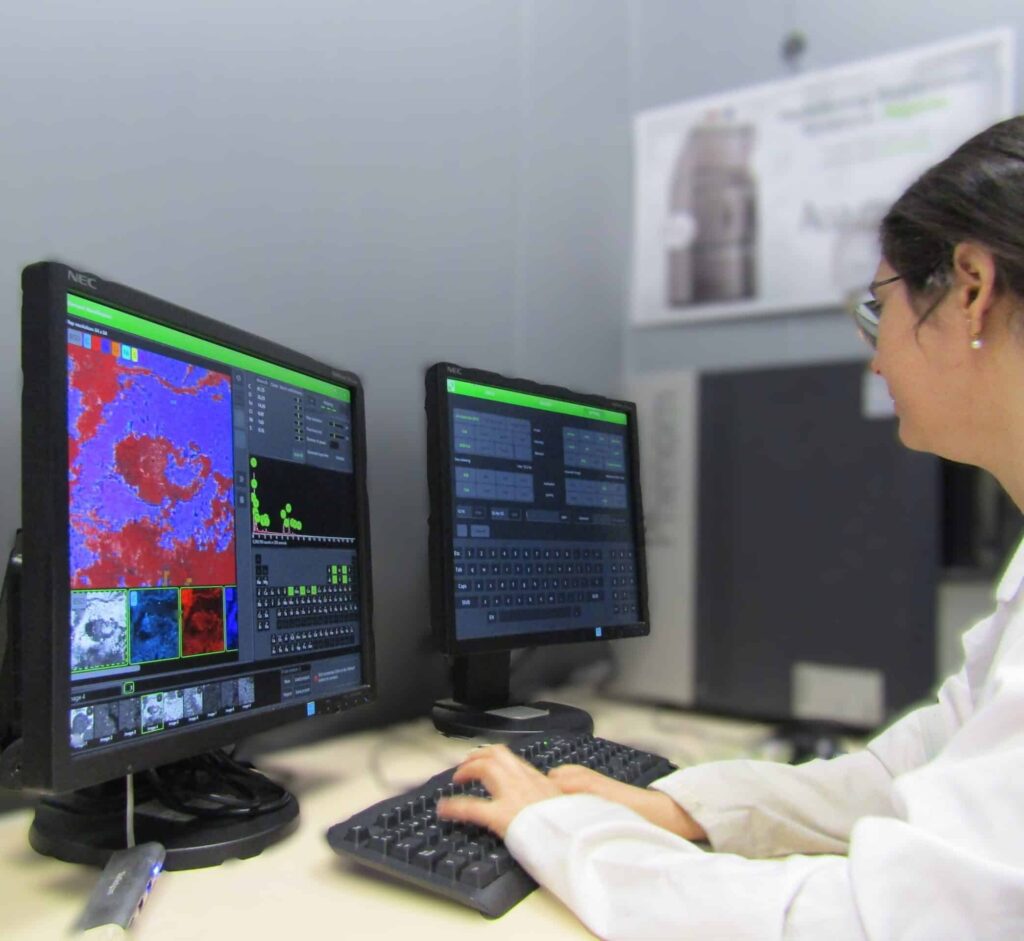

In our industrial laboratory, we have a team of failure analysis and forensic engineering specialists who use state-of-the-art technologies to study defective samples (NOK), simulate real failure conditions and validate hypotheses through material testing. This structured and technical approach allows us to act effectively from the outset.

What is the root cause diagnosis of the failure?

Root Cause Analysis (RCA) is a systematic process aimed at finding the real origin of a technical problem, beyond its apparent symptoms.

At INFINITIA we develop this diagnosis by applying structured methodologies such as 8D analysis, Ishikawa diagram or cause-effect analysis.

These approaches allow us to formulate strong hypotheses, establish cause-effect relationships, and design targeted tests to validate those hypotheses. The process usually involves comparison between OK and NOK samples, direct in-plant observation and technical analysis in the laboratory.

Depending on the case, it can be extended with material characterization techniques, reverse engineering or accelerated testing. This versatility allows us to adapt to the requirements of each customer and sector, guaranteeing reliable and actionable results.

Benefits of root cause failure diagnosis

One of the main advantages of root cause failure diagnosis is its ability to prevent errors from recurring. At INFINITIA we do not limit ourselves to identifying what went wrong, but go one step further, detecting patterns and hidden factors that could trigger new failures in the future. This allows us to make informed decisions on redesign, supplier validation, process improvement or material selection.

In sectors such as automotive, household appliances, consumer goods or chemical industry, we have helped to reduce costs associated with returns, field failures or warranties, thanks to an accurate and results-oriented analysis. The knowledge generated in these studies becomes a strategic tool for the continuous improvement of our clients.

Root cause diagnosis of the INFINITIA failure

At INFINITIA Industrial Consulting we approach each diagnosis with a rigorous methodology, adapted to the context of the failure and the client’s objectives.

We have an industrial laboratory equipped to carry out physical, chemical and functional analysis, as well as advanced material characterization techniques. But what really sets us apart is our ability to combine technical analysis with direct observation of the production environment.

Our team travels to the plant to gather key information, interview personnel, observe the failure in situ and understand how system variables interact. This proximity, together with the use of tools such as hypothesis validation, comparative analysis and failure simulation, allows us to offer a useful, fast diagnosis with a high impact on decision making.

Types of root cause failure diagnosis

At INFINITIA we adapt our diagnostic methods to the particularities of each failure, material or system involved. These are the most relevant types of diagnosis we perform:

Comparative diagnosis of OK and NOK samples

This type of diagnosis is based on the direct comparison between a defective sample (NOK) and a functional sample (OK). The objective is to detect differences in composition, geometry, surface treatment or service conditions that may explain the failure. This is a very effective technique when the origin of the defect is not obvious to the naked eye. At INFINITIA, this approach is complemented by physico-chemical analysis and validation tests to confirm the hypotheses detected.

For example, a customer in the industrial sector, we identified differences in composition between OK and NOK cable tracks that caused functional failures in an electrical component after assembly.

Structured diagnosis using root cause analysis tools

We use methodologies such as the Ishikawa diagram or cause-effect analysis to structure all possible causes of failure. This systematization allows us to prioritize hypotheses and plan the next steps of the study. This approach is aligned with methodologies such as 8D analysis, which we follow in cases where the failure involves multidisciplinary teams or affects the quality of the final product.

At INFINITIA we have used this approach with several clients and industrial sectors to identify the interaction between metallic coatings and certain chemicals that generated premature corrosion.

Validation of hypotheses through technical tests

Once the possible causes have been formulated, we design specific material tests to validate them: impact, tensile, corrosion, accelerated aging, among others. This approach is key to reduce analysis times and avoid misinterpretations. From our industrial laboratory, we perform these tests with high precision instruments, applying international standards or protocols adapted to the client.

An example at INFINITIA is the analysis of cracks in plastic parts through impact and aging tests which has allowed the reformulation of materials in consumer products to increase their durability

On-site diagnostics

We perform technical inspections directly at the customer’s facilities to observe the failure in its real context. This direct observation allows us to detect undocumented variables, environmental anomalies or human errors that might go unnoticed in the laboratory. This approach is particularly useful in complex processes or environments with high interaction between operators, equipment and materials.

An example of this was a case in which our team investigated the breakage of concrete counterweights in situ in order to subsequently determine the origin of the problem by simulating the failure under controlled conditions.

In cases where the failure cannot be easily observed or requires special conditions, we reproduce the problem under controlled conditions through simulations. These tests help us to confirm hypotheses and understand the failure mechanism at a functional level. A common example is the reproduction of cracks in plastics due to fatigue or aging, which allows us to validate redesign alternatives or new materials.

Sectors in which root cause failure diagnosis is applied

Automotive

In this sector, failures can have critical consequences. We apply RCA (Root Cause Analysis) to investigate structural failures, defects in plastic parts or electrical problems. Comparative analysis and failure simulation are key tools to validate design or supplier alternatives.

Household appliances and consumer goods

We perform functional failure studies on components subjected to thermal cycles, humidity or wear. The technical diagnosis allows us to detect hidden causes such as manufacturing defects or incompatibility of materials, which has a direct impact on the durability of the product.

Electronics industry

Failures are often related to solder joints, circuit leads or potting. We combine material characterization with microscopy, thermal analysis and sample-to-sample comparison techniques to pinpoint the root cause.

Chemical and pharmaceutical industry

In these environments, the interaction between substances can cause unexpected failures in containers, coatings or components in contact with reactive products. We apply compatibility, corrosion and aging analyses to prevent these problems and validate safe alternatives.

Packaging industry

We analyze defects in multilayer films, ink migrations or breaks in transport conditions. Direct observation of processes and cause-effect analysis help to prevent returns or logistical losses.

Energy and renewables

We evaluate failures in systems subjected to extreme conditions: heat, humidity, vibration. INFINITIA uses fatigue tests, thermal characterization and structured analysis to guarantee the reliability of critical components.

The strategic value of root cause failure diagnosis with INFINITIA

In an increasingly competitive industrial environment, the diagnosis of the root cause of failure has become a key tool for improving the reliability, safety and performance of products and processes. This service allows not only to solve a specific problem, but also to generate knowledge applicable to the entire value chain.

At INFINITIA Industrial Consulting, we integrate this approach within a global strategy of continuous improvement, helping our clients to prevent recurrences, optimize costs and reduce the impact of failures in the market.

Throughout the process, we apply structured methodologies such as 8D analysis, Ishikawa diagram or RCA (Root Cause Analysis), and combine them with advanced material characterization techniques, validation tests and failure simulation. All this is carried out in our industrial laboratory, with the support of a multidisciplinary team with experience in sectors such as automotive, electronics, consumer goods or chemical industry.

In addition, our methodology includes a critical phase of on-site observation, where we collect qualitative and quantitative information directly in the plant. This direct contact with the failure environment allows us to provide more accurate, faster diagnoses and actionable recommendations.

Relying on INFINITIA to carry out the initial fault diagnosis provides a tangible competitive advantage: it turns a technical problem into an opportunity to innovate, improve and differentiate. And all this with the support of an expert team, agile and committed to the success of our customers.