Metallographic Testing

Metallographic testing is a fundamental technique in the field of materials engineering, as it allows for detailed study of the internal structure of metals and alloys.

At INFINITIA, we use this service to characterize microstructures, identify defects, and evaluate heat treatments or manufacturing processes.

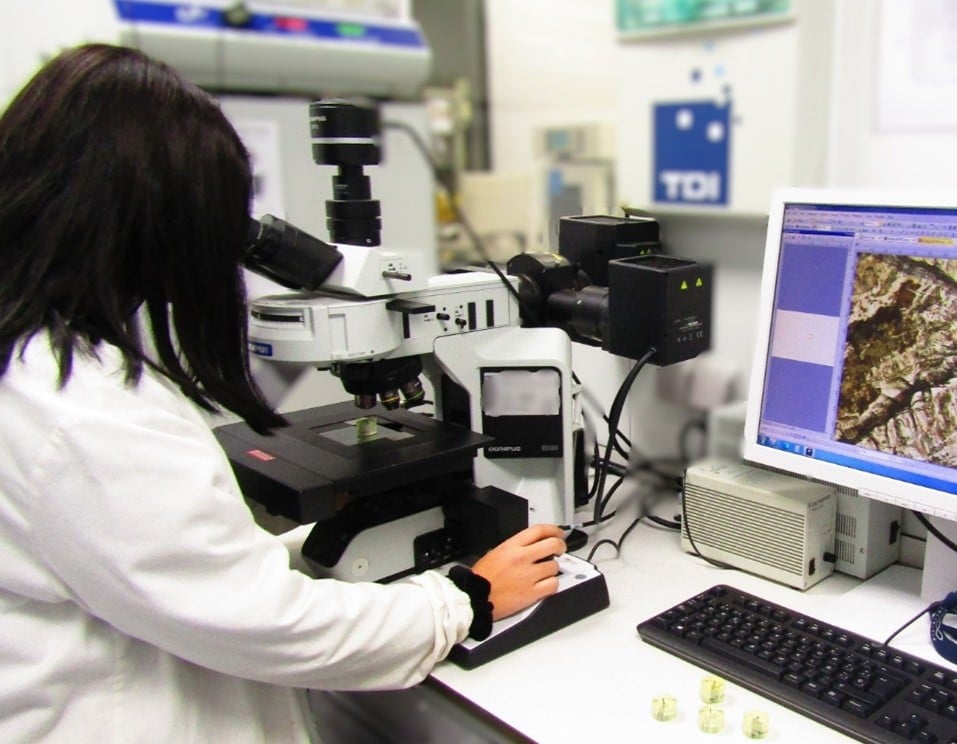

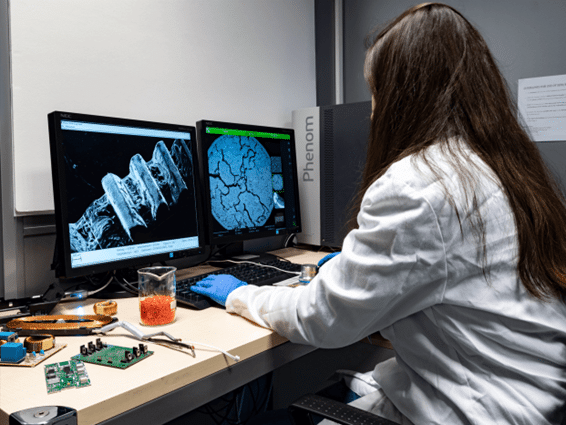

In our industrial laboratory, we have highly qualified specialists and state-of-the-art equipment for sample preparation, optical microscopy, and electron microscopy (SEM-EDS).

Thanks to this approach, the metallographic tests carried out at INFINITIA provide companies with accurate and reliable data, which is key to material validation, fault diagnosis, and quality control in demanding industrial sectors.

What does metallographic testing involve?

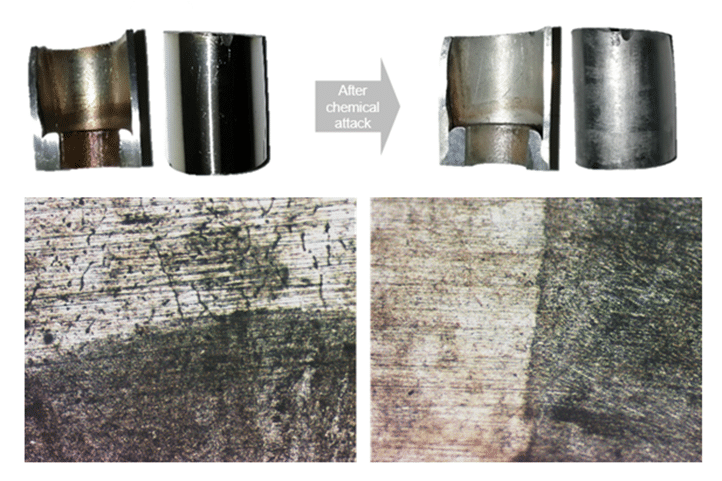

Metallographic analysis consists of studying the microstructure of a metallic material through a rigorous process that includes sample preparation, chemical etching, and observation using microscopy.

This procedure reveals details such as grain size, phase distribution, the presence of inclusions, cracks or porosity, and the effects of heat treatments applied to the material.

At INFINITIA, we adapt the methodology to each case: from destructive testing with cutting and polishing to in situ metallographic replication techniques that allow components to be analyzed without removing them from service.

The data obtained is essential not only for characterizing the material, but also for anticipating its mechanical behavior, corrosion resistance, and durability under real service conditions.

Benefits of metallographic testing

One of the main benefits of metallographic testing is its ability to detect and understand failure mechanisms in metal components. At INFINITIA, we have applied this service in reverse engineering and failure diagnosis projects, where microstructural characterization was decisive in identifying the root cause of fractures, localized corrosion, or fatigue failures.

In addition, metallographic analysis facilitates the optimization of manufacturing processes (such as welding, heat treatment, or casting) and supplier approval, ensuring that materials comply with international standards (ASTM, ISO) and the technical requirements of each sector. In short, it is a tool that provides reliability, safety, and efficiency throughout the entire industrial value chain.

Metallographic testing at INFINITIA

At INFINITIA, we approach metallographic testing with a comprehensive approach that combines scientific rigor, technical precision, and industry-focused vision. Our laboratory has advanced equipment for cutting, embedding, and polishing samples, specific reagents for chemical development, high-resolution optical microscopy, and electron microscopy with elemental analysis (SEM-EDS).

We also use specialized software to perform quantitative analyses of grain size, phase percentage, and inclusion density. This level of detail allows us not only to characterize materials, but also to advise companies on improving processes and products.

With its experience in forensic engineering and materials characterization, INFINITIA is positioned as a strategic partner for metallographic analysis, providing solutions that guarantee quality, durability, and competitiveness in complex industrial environments.

Types of Metallographic Tests

At INFINITIA, we develop different metallographic tests to analyze the microstructure, phases, and defects present in metallic materials. Our goal is to accurately understand the behavior of each alloy or metallic component, optimizing its application, functionality, and useful life in demanding industrial environments.

Optical microscopy tests

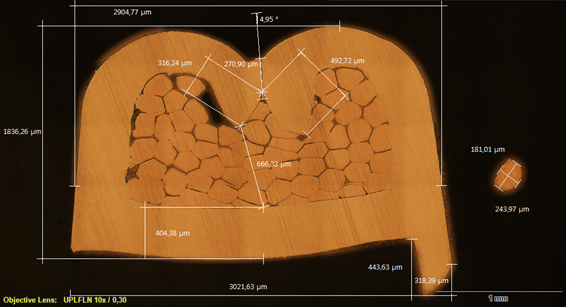

Optical microscopy tests provide detailed images of the metal microstructure, revealing grain size, phase distribution, and the presence of inclusions or defects.

At INFINITIA, we prepare samples by cutting, embedding, and polishing, then applying a chemical etch with specific reagents to highlight the structures. This technique is essential in quality control and heat treatment validation, as it provides direct information on the homogeneity and condition of the material.

Electron microscopy tests (SEM-EDS)

The use of scanning electron microscopy (SEM), combined with energy dispersive spectroscopy (EDS), allows metal surfaces to be observed at high magnification and localized chemical analyses to be performed.

At INFINITIA, we use this technique to characterize inclusions, identify contaminants, or determine precipitates in steels and special alloys. A common example is the validation of critical welds in the automotive industry, where SEM-EDS helps us detect microcracks and segregations in the heat-affected zone.

Fractography is the study of fracture surfaces, which is essential for understanding the failure modes of materials. In our laboratory, we apply this technique to differentiate between brittle, ductile, fatigue, and stress corrosion fractures.

Using SEM, we can observe characteristic patterns that allow our clients to implement corrective actions in their design or manufacturing processes. For example, in a mechanical component with premature failure, fracture analysis confirmed a tempering defect in the base steel.

In situ metallographic replicas

In situations where it is not possible to remove the service component, INFINITIA offers an on-site metallographic replica service, which allows the microstructural condition of a part to be assessed without the need to dismantle it.

This technique is particularly useful in preventive maintenance in sectors such as energy and petrochemicals, where it is crucial to detect degradation phenomena such as grain growth or carbide formation in steels subjected to high temperatures.

Quantitative analysis of microstructures

In addition to qualitative observation, at INFINITIA we use image analysis software to measure parameters such as grain size, inclusion density, and the percentage of phases present.

This quantitative approach is essential for verifying compliance with international standards (ASTM, ISO) and documenting the quality of materials in approval processes.

Applications of Metallographic Testing

Metallographic testing has strategic applications in multiple industrial sectors. At INFINITIA, we help companies in the automotive, aeronautics, energy, construction, and other fields to validate materials, anticipate failures, and ensure the reliability of their products.

Automotive Industry

In the automotive industry, where safety and reliability are critical, metallographic testing is used to analyze welds, components subjected to fatigue, and heat treatments.

- Validation of welded joints using optical microscopy and SEM-EDS.

- Evaluation of carburizing and tempering treatments in gears.

- Detection of non-metallic inclusions in components that could compromise their strength.

Aeronautical Industry

In aeronautics, light metals and superalloys must meet strength and durability requirements. INFINITIA performs metallographic testing on titanium, aluminum, and nickel.

- Phase analysis in superalloys.

- Study of fatigue cracks in aeronautical components.

- Validation of heat treatments in critical components.

Energy Sector

In power plants, refineries, and chemical plants, metal components operate under extreme conditions of temperature and corrosion. In-situ metallographic replication is key to preventing catastrophic failures.

- Evaluation of grain growth in high-temperature pipes.

- Analysis of stress corrosion in boilers.

Control of microstructures in stainless steels and refractories

Metallographic testing ensures the conformity of steels and welds in civil structures.

- Microstructural characterization in reinforced concrete steels.

- Analysis of welded joints in metal structures.

- Detection of defects in materials exposed to corrosive environments.

Manufacturing Industry and Suppliers

In approval processes, metallographic testing is crucial for selecting suppliers and validating raw materials.

- Comparison of steels from different manufacturers to optimize cost and quality.

- Evaluation of heat treatments applied by suppliers.

- Analysis of microstructures in accordance with international standards.

Metallographic Testing with INFINITIA

Metallographic testing is an essential tool for modern industry, as it provides detailed information on the microstructure and defects of metallic materials, anticipates failure mechanisms, and ensures that manufacturing processes comply with the most demanding standards. We have seen how optical and electron microscopy, fracture analysis, and in situ replicas provide a complete picture of the internal state of metals and alloys.

At INFINITIA, we not only apply these techniques with scientific rigor and technical precision, but also integrate them into a forensic engineering and materials characterization approach, allowing us to provide added value to our customers. Thanks to our specialized laboratory and the experience of our engineers, we offer solutions tailored to each sector: from automotive and aeronautics to energy, construction, and manufacturing industries. This knowledge allows us to detect faults, optimize processes, and validate suppliers with maximum reliability.

The future of industrial metallography points towards a greater degree of digitization, with advanced image analysis software, data integration in quality control environments, and the application of artificial intelligence techniques to identify microstructural patterns. INFINITIA is at the forefront of these innovations, committed to an approach that combines science, technology, and industrial application.

Having INFINITIA as a strategic partner in metallographic testing is a guarantee of quality and competitiveness. Our commitment is to provide each company with the critical information it needs to improve its materials and processes, anticipate problems, and ensure the durability of its products. With INFINITIA, metallographic analysis becomes a tool not only for diagnosis, but also for innovation and continuous improvement.