Preventive Failure Analysis

Preventive failure analysis is a fundamental strategic tool for ensuring the reliability, durability and safety of industrial components, materials and systems.

At INFINITIA, we apply this service to anticipate possible incidents during the useful life of a product, optimizing the design, manufacturing process and maintenance.

Our team specialized in forensic engineering works in INFINITIA’s industrial laboratory with advanced technologies, developing customized tests to detect critical conditions and avoid hidden defects that could lead to functional or structural failures.

Wha does preventive failure analysis consist of?

Preventive failure analysis is the application of scientific, advanced characterization techniques and physicaltests , chemical or mechanical to assess the reliability of a material or system prior to failure.

At INFINITIA we approach this process through analysis in real or simulated conditions, studying factors such as temperature, humidity, mechanical stress or exposure to chemical agents. The methodology can include from the use of thermographic cameras and spectroscopy, to accelerated corrosion tests or chemical resistance . The aim is to identify failure modes, validate hypotheses and make data-driven decisions before the product enters service.

Advantages of preventive failure analysis

One of the main benefits of preventive failure analysis is the ability to eliminate potential risks before they materialize, thus reducing costs associated with unplanned downtime, rework, returns or claims.

It also improves predictive maintenance processes, extending the useful life of components and optimizing the performance of equipment in sectors such as automotive, household appliances and the food industry. Thanks to this proactive approach, companies can make safer decisions regarding materials, processes and suppliers, consolidating their competitiveness and reputation in the market.

Preventive failure analysis at INFINITIA

At INFINITIA we carry out preventive analysis both in the laboratory and in the plant, adapting our technical capabilities to the real context of the customer. We perform aging simulations, tests to fail, comparative analysis of NOK/OK samples, and on-site diagnosis using portable measurement equipment.

Our tests comply with industry and international standards (such as ISO or ASTM) and are designed with a specific approach to each need. We provide an integral vision based on forensic engineering and material characterization, detecting critical points before functional, structural or aesthetic failures appear.

Types and applications of preventive failure analysis

At INFINITIA we approach preventive failure analysis from different approaches, depending on the type of material, product or process to be evaluated. These are some of the most relevant types:

Factory control and preventive analysis

With the help of our experts, we take the tests to where the problem occurs. We apply measurement and diagnostic techniques directly at the customer’s site, allowing us to analyze under real conditions, detect critical patterns and establish customized corrective measures.

In a real case, we used a thermographic camera to analyze the thermal behavior of machinery in operation. This monitoring made it possible to detect areas at risk of overheating and to define a routine control plan. As a result, the company was able to extend the service life of components and reduce the costs associated with unplanned corrective maintenance.

On-site diagnosis and root cause analysis:

We perform studies directly at the customer’s plant to identify hidden causes of failure. We often combine this approach with root cause analysis (RCA), Ishikawa diagrams or 8D methodology, allowing us to validate hypotheses without dismantling the line or interrupting the production flow.

For example, on one production line we observed a recurring failure in a silicone used during the process. After analyzing the material in the lab, we discovered that the failure coincided with a change in the opacity of the silicone. Based on this finding, we helped the customer implement an in-line turbidity detection system, which allowed them to identify the exact moment when the material needed to be replaced, optimizing both the process and preventive maintenance.

Tests to fail (tests to fail)

Specific tests are designed to induce failures in a controlled manner, in order to identify the real operating limits of a component. These tests make it possible to evaluate the mechanical, chemical or thermal resistance of materials under extreme conditions. A common example is the accelerated corrosion test on stainless steel using a potentiostat, ideal for estimating service life in harsh industrial environments.

Reliability analysis under real conditions

Through portable instrumentation and in-plant observation techniques (such as thermographic cameras or sensors), we evaluate the behavior of machinery and production lines without having to stop the process. This is essential for detecting overheating, misalignment, frictional wear or degradation of materials by external agents.

Accelerated aging tests

we simulate the passage of time on materials by exposing them to intensified conditions of temperature, humidity, chemicals or thermal cycles. This allows us to predict premature deterioration and adjust technical specifications prior to product launch. This is common practice in industries with stringent durability requirements in the industrial and product development phases.

Comparative analysis of NOK/OK materials

Using material characterization techniques (such as electron microscopy, spectroscopy, thermal analysis, etc.), we compare defective samples versus functional samples. This helps us to detect critical manufacturing variables and to redesign processes to prevent the occurrence of failures.

Sectors in which preventive failure analysis is used

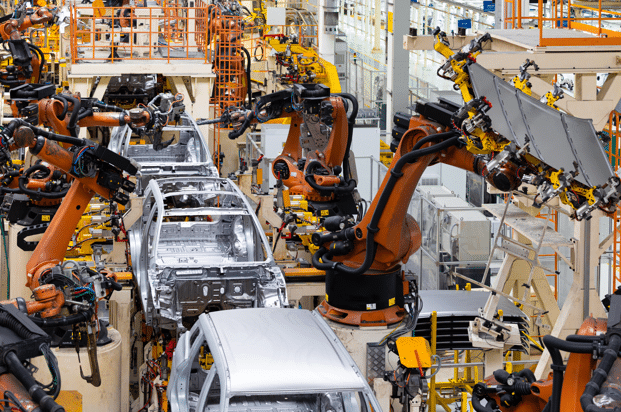

Automotive

In this sector, reliability and safety are key elements. We apply accelerated testing, material analysis and durability assessment in real conditions to ensure that components such as seals, connectors or metal parts withstand the demands of prolonged use. Preventive analysis helps reduce post-sales incidents and improve supplier certification.

Food industry

Equipment and materials in contact with food must be resistant to aggressive cleaning products, intense thermal cycles and high humidity conditions. At INFINITIA we perform chemical resistance tests and validation of material compatibility to avoid contamination or premature deterioration. This is especially useful for redefining technical data sheets and complying with regulations.

Household appliances

We evaluate the reliability of plastic and metal components against repeated cycles of use, exposure to moisture or chemical attack. A frequent case is the preventive analysis of failures in metallic coatings, where the objective is to avoid aesthetic and structural failures before commercialization.

Manufacturing industry in general

In mass production environments, preventive analyses help to validate alternative materials, reduce maintenance costs and guarantee operational continuity. INFINITIA also advises in design phases to establish technical criteria to minimize risks from the beginning of the project.

Anticipating failure, investing in reliability

Preventive failure analysis has become an essential tool for any industry that aspires to reduce risks, optimize costs and ensure maximum reliability of its products and processes. This service allows early detection of weaknesses in materials or operating conditions that could lead to failures during the product’s life cycle, enabling corrective action to be taken even before the problem materializes.

At INFINITIA, we integrate this preventive approach at every stage of the industrial cycle: from design and material selection to in-plant control and validation under real conditions. Our team combines forensic engineering expertise, advanced material characterization techniques and on-site analysis tools to provide accurate, customized and immediately applicable diagnostics.

In an increasingly demanding and competitive industrial context, anticipating failure is not only a technical advantage, but also a strategic one. Minimizing the impact of claims, avoiding production stoppages and reinforcing the quality perceived by the customer are direct benefits of betting on this type of analysis.

Having INFINITIA as a technology partner allows companies to address reliability challenges with a comprehensive vision, objective data and customized solutions. Because prevention is not just about avoiding failures: it is about building a more robust, profitable and sustainable industrial future.