3D design and modeling using CAD

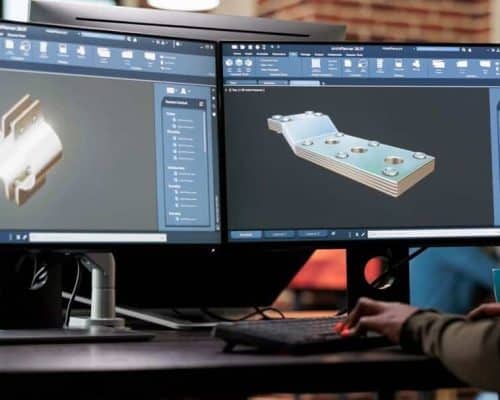

3D design and modeling using CAD (Computer-Aided Design)is a key tool in the product developmentindustrial, as it allows the creation, simulation, and optimization of digital models with great precision. In INFINITIA Industrial ConsultingWe use this advanced technology to transform ideas into tangible products, reducing development times and improving production efficiency.

Our industrial laboratory has highly qualified specialists and state-of-the-art tools to offer design solutions that adapt to the technical requirements of each sector. Discover what we can do for your project.

What is 3D design using CAD and 3D product modeling?

3D design using CADis 3D modeling. A process of digitally modeling parts and components in a virtual environment, using specialized software to define every detail of a product’s geometry and functionality. This technology can be used to simulate structural tests, analyze materials, and predict potential failures before manufacturing.

At INFINITIA, we take 3D CAD design to the next level by using cutting-edge software and advanced modeling methodologies. The combination of a modern infrastructure and a multidisciplinary team of design and engineering experts allows us to develop Customized solutions for each client.

We apply this methodology in various product development projects, from the creation of prototypesto the optimization of existing designs through reverse engineering and advanced simulations.

Benefits of 3D design with CAD software in product design

One of the main benefits of 3D CAD design is the precision and flexibility it brings to product development. Thanks to this technology, companies can reduce production costs, minimize errors, and improve the quality of the final product.reduce production costs, minimize errors, and improve the quality of the final product.

We innovate through CAD design, optimizing your products with efficient modeling and virtual performance testing. In sectors such as automotive, manufacturing, and product engineering, the use of CAD allows us to streamline processes, optimize materials, and ensure functionality in the design for manufacturing.

3D design and CAD modeling at INFINITIA. From concept to 3D prototype and additive manufacturing.

At INFINITIA, we take 3D CAD design to the next level by combining cutting-edge technological infrastructure with a team of experts in product engineering. Our industrial lab is equipped with advanced simulation systems, 3D scanning, and metrology, allowing us to integrate digital modeling with processes such as prototyping, manufacturing, and quality control. 3D scanning, and metrology, allowing us to integrate digital modeling with validation and prototyping processes.

In addition, we apply methodologies based on forensic engineering to detect possible failure modes in the design phase, preventing future problems and ensuring that each component is optimized for its final application. Thus, companies that place their trust in us not only obtain an accurate design, but also scientific and technical support that guarantees product reliability.

Types of 3D design using CAD and 3D CAD modeling

At INFINITIA, we develop different types of 3D CAD designs to meet the technical requirements of a wide range of sectors. Our goal is to offer precise and functional digital modeling, facilitating the workflow in the design of parts, which allows us to optimize product development processes, reduce costs, and guarantee manufacturing efficiency.

Parametric modeling

Parametric modeling allows you to define geometries using parameters and constraints. This way, any change is automatically propagated throughout the design, ensuring consistency and reducing errors.

At INFINITIA, we apply this technique in mechanical design and manufacturing projects, allowing us to modify components without having to start from scratch and reuse configurations in different products. Thanks to this methodology, we optimize the flexibility and efficiency of 3D design in industrial environments.

Surface modeling

Surface modeling focuses on creating complex, fluid shapes, ideal for automotive design or the aeronautical industry. With this technique, we generate high-quality surfaces for aerodynamic structures, aesthetic casings, or parts with free geometries.

At INFINITIA, we work with advanced CAD technologies to develop designs that not only fulfill a structural function, but also add value in terms of aesthetics and ergonomics.

Solid modeling

Solid modeling is the foundation of industrial CAD design, as it allows for the generation of detailed 3D representations with complete information on volume, material, and assembly.

At INFINITIA, we use it to validate the feasibility of parts, identify interferences in mechanical assemblies, and anticipate manufacturing issues. This technique is essential in sectors where dimensional accuracy and structural strength are crucial.

Mesh modeling

Mesh-based modeling is used in reverse engineering and digitization of existing parts. It allows components to be reconstructed from 3D scanning, facilitating design optimization or the creation of digital replicas using CAD software.

At INFINITIA, we use this methodology for 3D printing projects, component adaptation, and industrial part redesign, accelerating the rapid prototyping process.

Generative design and topological optimization

Generative design and topological optimization are advanced methodologies that apply algorithms to create structures optimized for mechanical and material requirements.

At INFINITIA, we integrate these techniques into aerospace and automotive projects, reducing component weight, improving strength, and optimizing the use of materials in additive manufacturing.

Applications of 3D Design using CAD in different industrial sectors

3D CAD design is a key tool in many industrial sectors, as it allows you to create accurate and functional models, reduce physical iterations, anticipate design problems, optimize manufacturing costs, and accelerate time-to-market. Through digital modeling, it is possible to validate concepts, simulate real-world conditions of use, and make informed technical decisions before manufacturing.

At INFINITIA, we develop precise, functional, and manufacturing-oriented 3D designs, adapting our CAD processes to the specific needs of each sector, whether for the development of new products, the improvement of existing components, or the validation of technical solutions.

Automotive Industry: 3D design and AutoCAD modeling of components for structural optimization

In the automotive sector, 3D CAD design is essential for developing bodywork, chassis, and mechanical components that must meet strict requirements for safety, durability, energy efficiency, and aerodynamics. Digital modeling allows multiple scenarios to be analyzed before moving on to prototyping or production phases.

- Aerodynamic simulations to validate body efficiency and reduce fuel consumption.

- Analysis of mechanical fatigue in parts subjected to repetitive load cycles.

- Structural optimization of components to reduce weight without compromising strength.

- Geometric adjustment of parts to facilitate assembly and maintenance.

Defense and Aerospace Industry: 3D CAD design and parametric modeling of lightweight and safe structures

The aerospace and defense industry demands designs of the highest precision, with very tight tolerances and compliance with international regulations. The use of 3D CAD and parametric modeling allows for the development of lightweight, robust structures that can be easily adjusted to changing requirements.

- Topological optimization to lighten critical components while maintaining structural integrity.

- Advanced structural simulations to verify resistance to extreme loads.

- Development of metal and composite structures adapted to harsh environments.

- Efficient management of design revisions using parametric models.

Mechanical Engineering and Manufacturing: CAD mechanical design and CAD models for precision and efficiency

In mechanical engineering and manufacturing, 3D CAD design allows you to maximize precision, reduce manufacturing errors, and ensure product viability from the earliest stages of design. It is a key tool for both individual parts and complex assemblies.

- Design of molds, dies, and tools for production processes.

- Dimensional and geometric validation of complex mechanical structures.

- Simulation of assemblies to detect interference and assembly problems.

- Preparation of technical documentation and drawings for production.

Healthcare Industry: 3D design and CAD modeling of prosthetics and customized medical devices

In the healthcare sector, 3D CAD design enables the development of customized solutions tailored to the specific anatomy and needs of each patient, improving clinical and functional outcomes.

- Design of customized prostheses using digital modeling.

- Geometric optimization of medical implants through structural simulations.

- Integration with additive manufacturing to produce precise surgical devices.

- Development of functional prototypes for clinical and technical validation.

Architecture and Interior Design: Benefits of 2D and 3D Design with CAD Software for Planning and Visualization

In architecture and interior design, CAD design provides technical precision and realistic visualization that facilitates decision-making in the early stages of the project. 3D modeling allows you to anticipate construction problems and optimize the design of the space.

- Creation of detailed digital plans for complex architectural projects.

- 3D modeling of spaces, structures, and building elements.

- Lighting and shadow simulations to evaluate different scenarios.

- Coordination between technical disciplines using shared digital models.

3D Printing and Additive Manufacturing: 3D design service, 3D CAD modeling for product design, rapid prototyping, and validation

3D CAD design is the basis of additive manufacturing, as it allows for rapid prototyping, validation of complex geometries, and optimization of material usage prior to mass production.

- Development of functional prototypes using 3D CAD modeling.

- Validation of the mechanical performance of 3D-printed components, using CAD software to ensure compatibility.

- Optimization of geometries and materials to improve the durability of parts.

- Rapid design iterations to accelerate product development.

3D design service. How INFINITIA transforms ideas into products using 3D design and AutoCAD software.

3D CAD design has established itself as an essential tool in industrial product development, allowing companies to optimize every stage of the process, from initial conceptualization to final manufacturing. Thanks to its ability to generate precise digital models, simulate real-world conditions, and anticipate potential failures, this methodology has become a strategic factor in ensuring quality, reliability, and efficiency across various industrial sectors.

At INFINITIA Industrial Consulting, we have demonstrated that the advanced use of 3D CAD provides decisive competitive advantages. By integrating parametric modeling, surface design, solid modeling, and methodologies such as topological optimization, we offer our clients product engineering solutions tailored to their specific needs. Our industrial laboratory, equipped with state-of-the-art equipment, allows us to combine digital design with advanced simulation processes, 3D metrology and rapid prototyping, ensuring that each project is backed by technical and scientific rigor.

The importance of CAD design also lies in its versatility. In sectors such as automotive, aerospace, healthcare, manufacturing, and architecture, this technology enables lighter, safer, and more efficient designs, with shorter development cycles and greater control over the final functionality of the product. Looking ahead, trends such as additive manufacturing, generative design, and the integration of reverse engineering will mark new opportunities to further optimize processes and improve the performance of industrial products.

Relying on INFINITIA for 3D CAD design means having a strategic partner capable of transforming ideas into tangible, innovative solutions with high added value. Our multidisciplinary approach, based on a combination of forensic engineering, material characterization and validation testing, ensures that each design not only meets specifications, but is also prepared to overcome the challenges of today’s and tomorrow’s industry.