What is a Microbiology Room?

INFINITIA’s Microbiology Room is a specialised space for the study, handling and analysis of microorganisms under controlled biosafety conditions. Equipped with biosafety level 2 (BSL-2) infrastructure, it allows testing of both common and potentially pathogenic microorganisms, always under strict containment and safety measures. This environment allows bacteria and fungi to be studied in samples of different types, from industrial materials to consumer products. At INFINITIA, this room has been designed to meet the highest technical standards, inspired by best practices set out in international regulations on quality management and biosafety in laboratories.

How does the Microbiology Room work?

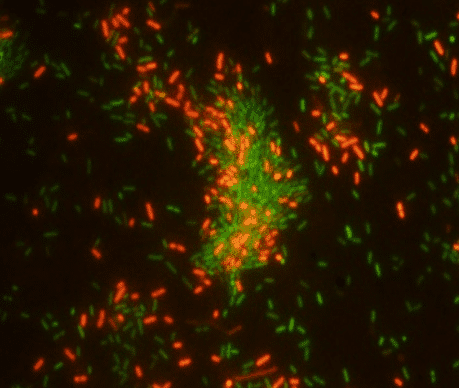

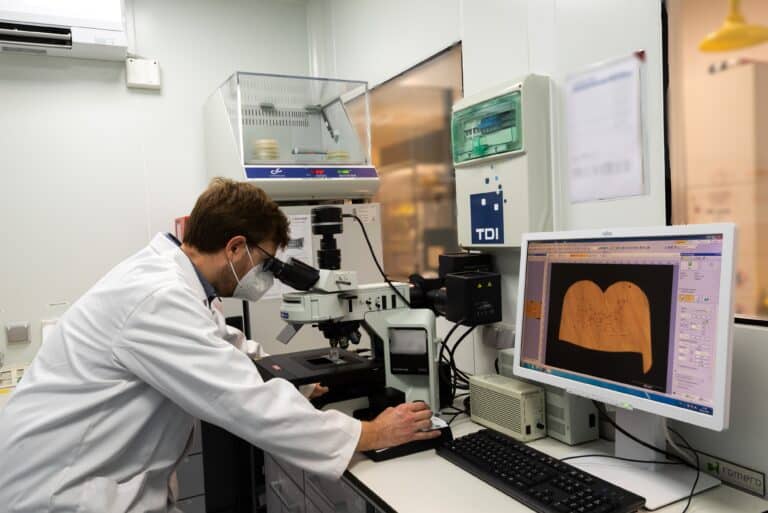

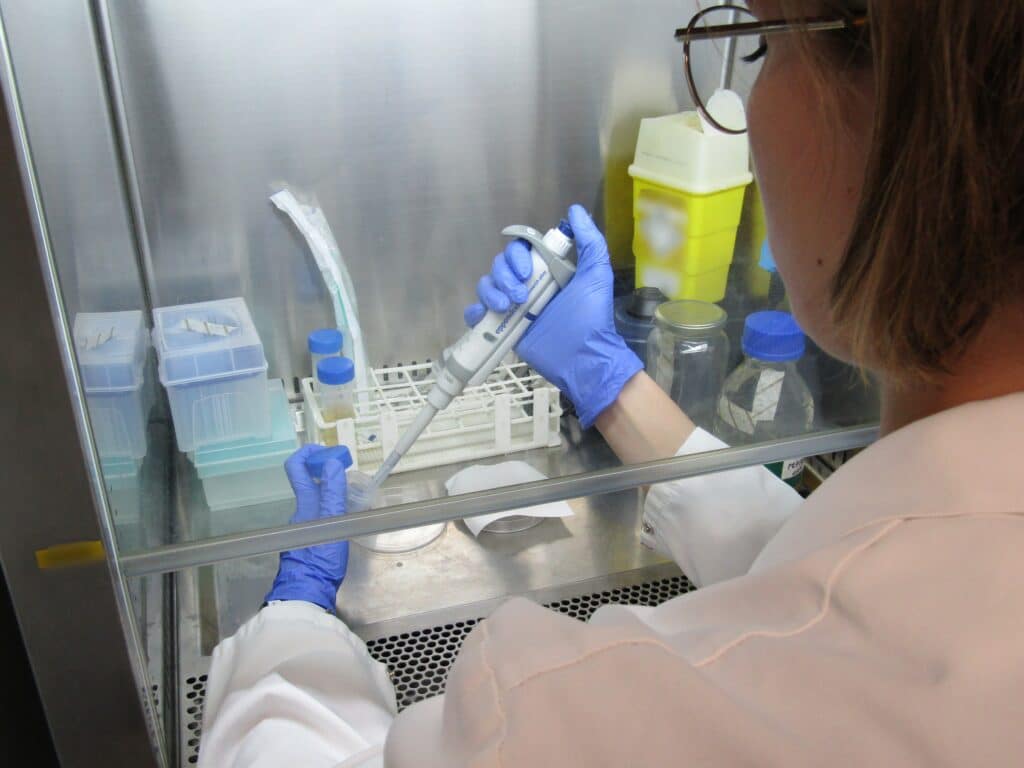

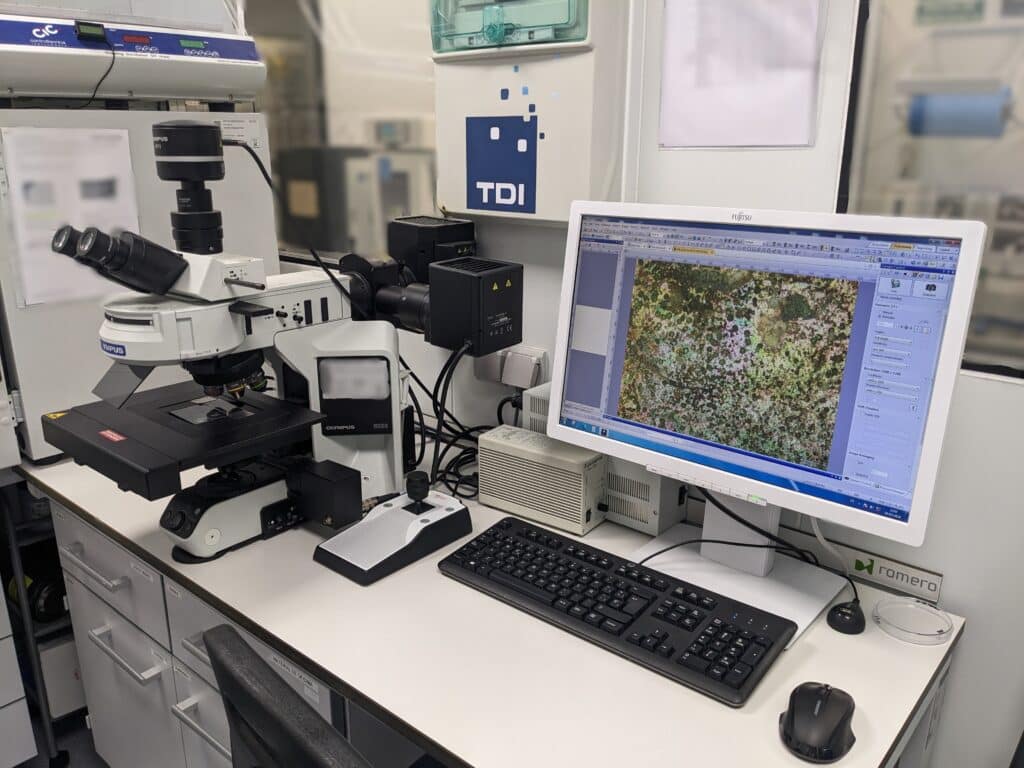

INFINITIA’s Microbiology Laboratory is equipped with laminar flow systems, an optical microscope with a specific epifluorescence module for staining and visualising microorganisms, and specific incubation systems for bacteria and fungi. This combination allows the entire experimental process to be carried out: from the isolation and culture of microorganisms to their quantitative and qualitative analysis. The strains used in the tests include both bacteria and fungi, and model microorganisms such as E. coli, S. epidermidis, C. albicans and S. aureus. The studies are carried out under safety protocols and standardised scientific methodology. In the case of antimicrobial and antibiofilm tests, international standards such as ISO 22196:2011 and JIS Z 2801:2010 are applied, which allow the efficacy of materials or treatments against microbial contamination to be rigorously evaluated.

Benefits of the Microbiology Room

The microbiology lab at INFINITIA offers unique versatility for tackling projects of varying complexity and microbiological risk.

The microbiology labs allow us to perform not only basic microorganism identification tests, but also advanced studies of the interaction between materials and pathogens.

This comprehensive approach offers key benefits in sectors such as forensic engineering, industrial quality control, and applied research into new antimicrobial technologies.

Furthermore, working under recognised regulations makes it easier for INFINITIA to collaborate on projects involving certification, approval of materials and validation of sanitation and sterilisation processes.

Equipment in the Microbiology Room at INFINITIA

The Microbiology Room model offered by INFINITIA combines equipment to cover a wide range of experimental needs.

This infrastructure allows everything from antimicrobial screening tests to the study of complex sanitisation processes using different technologies, adapting to different risk levels and sample types.

Compared to other laboratories, INFINITIA stands out for its ability to customise test protocols and design tailor-made studies for the industry, always guaranteeing technically validated results in accordance with international biosafety and quality best practices.

Applications of the INFINITIA Microbiology Laboratory

- Microorganism identification tests: At INFINITIA, the Microbiology Laboratory is equipped to carry out microorganism identification tests using advanced methods such as selective cultures, biochemical techniques and microscopic observation. Standardised protocols are applied to identify bacteria and fungi present in different types of samples, ensuring reliable and reproducible results. This type of testing is essential for quality control, forensic engineering research and the characterisation of industrial products, where the presence of microorganisms can compromise functionality or safety. INFINITIA performs microbiological identification tests using selective cultures, microscopic analysis and biochemical techniques. These tests allow the detection and classification of microorganisms present in a sample, whether of environmental, industrial or clinical origin. This service is essential for quality control, failure analysis and the validation of cleaning or sterilisation processes.

- Isolation and culture of microorganisms: The isolation and culture of microorganisms is one of the basic procedures in INFINITIA’s Microbiology Laboratory. Through the use of selective culture media and controlled environmental conditions, specific strains, such as E. coli, S. epidermidis or S. aureus, can be grown and studied in detail. Both environmental and industrial samples can be analysed to detect contamination, study cleaning processes or evaluate microbial proliferation in different materials. These capabilities allow us to simulate real conditions and obtain critical data for the design of prevention and control strategies.

- Analysis of the presence of microorganisms: The detection of microorganisms on surfaces, liquids or materials is one of the main applications in INFINITIA’s laboratories. Using methods such as plate counting, staining techniques and epifluorescent microscopy, the microbial load present in a sample can be quantified. This analysis is key to validating sanitation processes and ensuring that products comply with the microbiological requirements established by international regulations. In addition, the ability to work with different levels of biosafety allows for the analysis of both common contaminants and higher microbiological risks.

- Study of sanitation and cleaning processes: The validation of cleaning and disinfection processes in industrial environments requires a meticulous approach that only a few facilities, such as INFINITIA’s Microbiology Rooms, can offer. Specific tests are designed to reproduce the conditions of use of disinfectants and detergents, evaluating their effectiveness in eliminating bacteria and fungi. The results of these studies allow for the optimisation of sanitation protocols, improving the safety of final products and helping companies to comply with high standards in antimicrobial surface control.

- Study of disinfection and sterilisation techniques: INFINITIA carries out comparative tests to evaluate different technologies for disinfection (chemical, thermal, UV radiation, among others) and sterilisation processes applied to products, medical devices or industrial environments. These studies are carried out under controlled conditions, allowing the effectiveness of each technique to be determined according to the type of microorganism and the material treated. Thanks to this capability, it is possible to validate critical procedures for industries as diverse as pharmaceuticals, food and advanced manufacturing.

- Development and study of antimicrobial materials (JIS/ISO 22196 standard): One of the most innovative applications developed by INFINITIA in its Microbiology Laboratory is the evaluation of antimicrobial materials according to the standards mentioned above. Tests are carried out to measure antibacterial activity on surfaces, allowing the reduction of bacterial colonies in plastic, metal and coating materials to be quantified. These studies are essential for the certification of new products, the development of high added-value solutions and the improvement of health safety in sectors such as hospitals, food and construction.

- Study of the interaction between microorganisms and materials: Understanding how microorganisms interact with different materials is essential for designing surfaces that are resistant to biological growth. INFINITIA carries out detailed studies that analyse the adhesion, proliferation and formation of biofilms on materials subjected to different treatments or finishes. In turn, it is possible to define and carry out various types of accelerated tests to evaluate the behaviour of materials over years in just a few weeks or months. This line of research not only has applications in infection control, but also in improving industrial products exposed to humid or contaminated environments, such as automotive components, medical devices or water treatment systems.

INFINITIA’s Microbiology Room represents a strategic infrastructure for the development of tests for the identification, analysis and control of microorganisms under controlled biosafety conditions. Thanks to the availability of a room with a high level of biosafety, it is possible to work with both low-risk strains and higher-level pathogens, adapting to the specific needs of each project. The ability to carry out isolation studies, culture, microbial presence analysis, as well as to validate sanitation, disinfection and sterilisation processes, places INFINITIA at the forefront of applied research and microbiological quality control. In addition, antimicrobial material evaluation tests, in accordance with ISO 22196:2011 and JIS Z 2801:2010 standards, allow INFINITIA to actively collaborate in the development of innovative solutions for critical sectors such as healthcare, the food industry, automotive and construction.

The technical approach, based on standardised protocols, guarantees highly reliable results, which are essential for forensic engineering, product validation and the continuous improvement of industrial processes.

Looking to the future, trends in microbiology point to growth in studies on microorganism-material interaction, the development of self-cleaning surfaces and bioactive solutions, areas in which INFINITIA is already deeply involved.

At INFINITIA, we remain committed to innovation and the use of advanced technology in our laboratories to deliver accurate, high-quality results. Thanks to our experience and investment in state-of-the-art equipment, we guarantee efficient solutions tailored to the needs of industry.

Here are some examples of how the microbiology lab is used at INFINITIA: