Prototyping and prototype manufacturing

What is rapid prototyping and prototype manufacturing?

At Infinitia, we make your ideas a reality.To this end, we opted to launch product prototyping, with the aim of improving your project or making your idea tangible, bringing it to life through detailed product design.

We solve problems, seek production efficiency, research the viability of materials, and offer you a guarantee of quality and functionality. In short, the use of high-fidelity prototypes improves the validation of ideas. QWe want to offer you the best version of your product.That is why prototyping is so important.

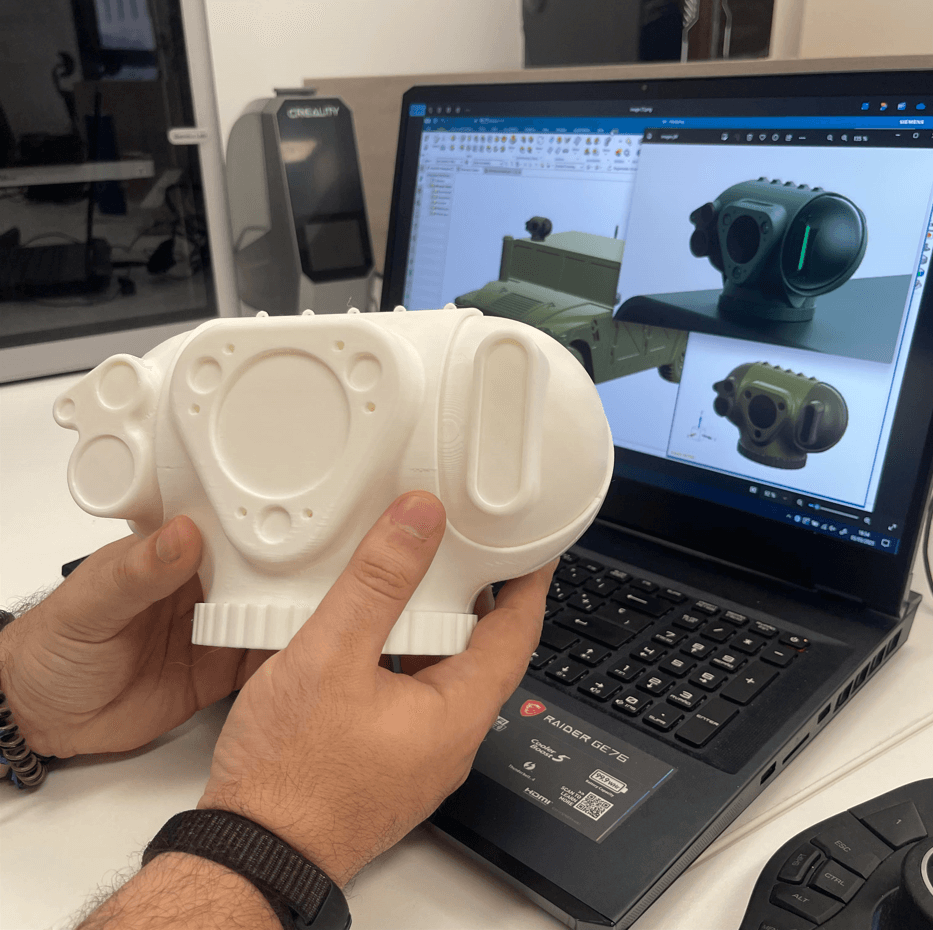

In our prototyping service, designers will transition between conceptual design, 3D CAD modeling, and prototyping to validate your ideas.conceptual design, 3D CAD modeling, and prototypingto validate their ideas. It is an iterative process in which new opportunities are revealed and problems that need to be explored and refined are highlighted.

We create prototypes to constantly validate our ideas.We use different techniques such as rapid prototyping, sketches, and appearance models. If you want your project to be effective and secure, the Infinitia team is here to help.

Benefits of product design, prototyping, and prototyping in manufacturing

One of the main benefits of prototyping is the ability to detect design errors and improve the user experience, material incompatibilities, or process limitations in the early stages of the project. At INFINITIA, prototyping allows companies to validate technical hypotheses, improve product performance, and adjust critical parameters before making significant investments in tooling or production lines.

In demanding industrial sectors such as automotive, capital goods, and manufacturing, the functional prototypes developed by INFINITIA have enabled design optimization, improved component durability, and ensured compliance with technical and regulatory requirements, contributing to a significant reduction in costs associated with serial failures and rework.

Advantages of Prototyping

Troubleshooting: Address prototype design and manufacturing issues early on, conduct tests to determine fit and durability in an iterative design process. All this with the aim of optimizing both the material and human resources of the project through an efficient design process.

Feedback: Receive feedback on the low-fidelity prototype from customers and end users to identify and implement the necessary improvements.

Experience: We have proven experience in developing tangible products and using different technologies throughout the various stages of development, including the creation of digital prototypes.

Adaptability: key in prototyping is a process that responds to the changing needs of the project. We adapt to your requirements, offering technological solutions to technical problems.

Greater flexibility and shorter development time:We provide comprehensive in-house development through our multidisciplinary team and have an extensive network of contacts to prototype a successful product. We estimate production costs, manufacturing time, and material requirements.

Feasibility:We are equipped to turn your ideas into functional prototypes, as well as to certify and industrialize them according to the requirements of the project to be developed. We have the necessary equipment and machinery for production.

What is a prototype and how do we approach the prototyping process at Infinitia?

At Infinitia, we carry out the development and construction of electronic, mechanical, and product prototypes in a rigorous and detailed manner.We want to offer you the best prototype for your project, so we invest time and effort in both its implementation and its various evaluations.

We believe that continuous prototype testing is very important throughout the process, as it allows us to resolve many issues, such as the durability of materials. Different tests, techniques, and methods to offer you the best product, including low-fidelity prototypes. From the creation of sketches or appearance models to the generation of high-fidelity rapid prototype models. The latter is in high demand in the industry thanks to its speed, low cost, and efficiency.

At Infinitia, we can help you bring that idea to life by creating a prototype of an innovative product, that idea that you have had in mind for a long time, thanks to our prototyping servicewe can help you bring that idea to life with a prototype of an innovative product, that ideathat you have had in mind for a long time, thanks to our prototyping service.

Types of prototyping and phases in prototype manufacturing

At INFINITIA Industrial Consulting, our prototyping and prototype manufacturing service adapts to the different needs of companies throughout the industrial product development process. Depending on the degree of maturity of the design, the technical objectives, and the functional requirements, we define the most appropriate type of prototype for each case.

Conceptual prototype

The conceptual prototype is used in the early stages of development to transform ideas and concepts into physical models that facilitate their analysis and preliminary validation. At INFINITIA, these prototypes allow us to explore constructive solutions, evaluate geometries, and support technical decision-making from the earliest stages of the project, using feedback from real users and user testing.

- Validation of geometries, volumes, and initial configurations through a high-fidelity prototype.

- Quick comparison of design alternatives using design thinking.

- Early identification of geometric or construction limitations

- Improvement of technical communication between engineering teams through feedback obtained during the prototype design process.

Working prototype

The functional prototype represents a more advanced level within industrial prototyping. At INFINITIA, it is manufactured using materials and processes representative of the final product, allowing its performance to be evaluated under real or simulated service conditions.

- Evaluation of the mechanical, thermal, and chemical behavior of functional prototypes in order to obtain valuable feedback.

- Validation of design hypotheses through technical testing

- Verification of product performance under representative conditions

- Technical risk reduction prior to industrialization

Validation prototype or pre-series

The validation prototype or pre-series is developed when the design is at an advanced stage and it is necessary to check its manufacturability, repeatability, and suitability for real industrial processes. INFINITIA approaches this type of prototype with a clearly production-oriented focus.

- Verification of actual manufacturing processes

- Tolerance analysis, assemblies, and adjustments

- Assessment of compliance with technical and regulatory requirements

- Robust preparation for series production

Custom or experimental prototypes

Custom or experimental prototypes are specifically designed for trials, proof of concept, or research and development projects. At INFINITIA, these prototypes enable us to validate innovative solutions and study specific technical phenomena under controlled conditions.

- Prototype development for proof of concept (PoC)

- Experimental validation of new materials and technologies to create a prototype that meets quality standards.

- Analysis of specific behaviors in controlled environments to validate user interfaces.

- Technical support for R&D and technological development projects, including the creation of digital prototypes to improve the efficiency of the design process.

Prototyping methodology at INFINITIA

The prototyping process at INFINITIA is based on a structured methodology that guarantees technical rigor, traceability of decisions, and risk reduction throughout product development.

Discussion and definition of the design

Each project begins with an analysis and technical definition phase, in which INFINITIA aligns the client’s objectives with the functional, regulatory, and usage requirements of the prototype, thereby improving the user experience.

- Analysis of technical and functional requirements for the development of a product or service.

- Definition of objectives and validation criteria

- Identification of critical points and technical risks

Engineering and design optimization

Based on the initial definition, INFINITIA develops and optimizes the design by applying engineering criteria focused on functionality, manufacturability, and future industrialization of the product.

- Development of the technical model for prototyping a product that meets customer expectations.

- Selection of materials and manufacturing technologies

- Design iterations to optimize performance and costs, saving time and money in the process.

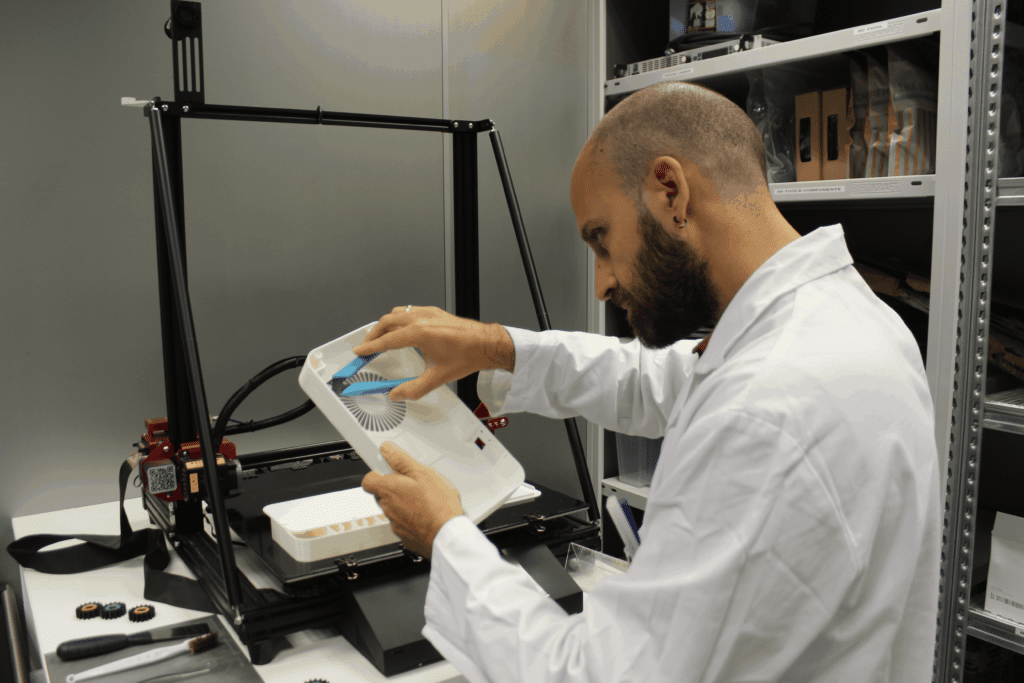

Manufacturing and technical evaluation

Once the design has been defined, the prototype is manufactured and technically evaluated through functional tests and trials that provide objective data on its performance.

- Manufacture of the prototype using appropriate industrial processes

- Functional testing and technical trials

- Analysis of results and iterative design improvement

Final validation and preparation for scaling up

In the final phase, INFINITIA verifies that the prototype complies with the technical specifications and expected performance, leaving it ready for industrial scaling or mass production.

- Verification of compliance with technical specifications

- Validation of operation under representative conditions

- Verification of regulatory and certification requirements

- Preparation for industrialization or pre-series production

Some examples and types of prototypes

Choosing the right technique for manufacturing the prototype is essential. From creating sketches or appearance models to generating rapid prototyping models. The latter is the most widely used in the industry today due to its speed, low cost, and efficiency.

Sketches

They are very useful at the beginning of the design process, as they help to understand an object and give a general idea of its design.

Appearance models

These are prototypes that resemble the final product but do not actually function. They are used to refine the appearance of a product and are especially useful when choosing the finish.

Rapid prototyping

It is a process by which we create objects in order to test our product before launching it on the market in an easy and inexpensive way. Creating a prototype usually costs hundreds of euros and hours of work. With rapid prototyping, thanks to tools such as 3D printing, lasers, or CNC milling, we can save costs and have our prototype ready on the same day.

Sectors in which prototyping is applied, prototype manufacturing, and examples of prototyping

Choosing the right technique for manufacturing the prototype is essential. From creating sketches or appearance models to generating rapid prototyping models. The latter is the most widely used in the industry today due to its speed, low cost, and efficiency.

Automotive Industry: rapid product prototyping for functional validation and risk reduction before mass production

The automotive industry requires highly reliable components capable of operating under severe conditions of mechanical load, vibration, thermal fatigue, and environmental exposure. At INFINITIA Industrial Consulting, high-fidelity prototyping allows manufacturers and suppliers to validate designs and materials prior to mass production, reducing the risk of field failures and optimizing development costs.

The functional prototyping developed by INFINITIA allows for the evaluation of complex geometries, critical assemblies, and real construction solutions, facilitating technical decision-making in the early stages of the project.

- Manufacture of functional prototypes for mechanical and dimensional validation.

- Evaluation of components subjected to vibration, impact, and thermal cycles.

- Prototypes for assembly, fit, and compatibility testing with other systems, including functional prototypes to validate the final design.

Aerospace and Energy: technical prototypes and advanced prototyping technology for extreme conditions and high functional demands

In the aerospace and energy sectors, products must meet extremely demanding requirements in terms of safety, reliability, and performance in extreme conditions. At INFINITIA, prototyping is used as a key tool to validate technical solutions before certification or industrial scaling.

Prototypes enable the analysis of the actual behavior of materials and components when exposed to high temperatures, prolonged mechanical stress, or corrosive environments, anticipating possible failure mechanisms.

- Prototypes for thermal and mechanical validation of critical components.

- Development of experimental parts for advanced functional testing using a design thinking approach.

- Manufacture of prototypes geared toward durability and reliability studies.

Manufacturing Industry and Capital Goods: rapid prototyping in manufacturing to optimize design and production processes

In industrial manufacturing environments, prototyping is an essential tool for optimizing designs, improving production processes, and reducing deviations between theoretical design and industrial reality. At INFINITIA, prototypes allow us to evaluate manufacturability, tolerances, and assembly processes before production begins.

This approach minimizes rework, late adjustments, and line stoppages, giving companies a clear competitive advantage.

- Prototypes for validating machining and assembly processes, including low-fidelity options.

- Evaluation of solutions using design thinking to improve the design process prior to industrial scaling, incorporating feedback from real users.

- Manufacture of pre-series to check repeatability and quality.

Medical Devices and Healthcare Sector: prototype manufacturing for functional validation, safety, and regulatory compliance

The medical device sector demands a high level of control in product development, where prototyping is key to validating the functionality, ergonomics, and performance of the device prior to certification. At INFINITIA, prototyping is integrated into development processes focused on product safety and reliability.

Prototypes enable technical testing, usability studies, and preliminary validation, reducing regulatory and technical risks.

- Functional prototypes for design and usage validation, enabling real users to provide essential feedback.

- Evaluation of materials and geometries in contact with the user.

- Development of prototypes for pre-certification testing.

Food Industry and Packaging: prototyping process and custom manufacturing for safe product development

In the food and packaging sector, prototyping allows technical solutions related to design, functionality, and compatibility with production processes to be validated. At INFINITIA, prototypes help evaluate new geometries, materials, and systems before their industrial implementation.

This approach reduces risks associated with functional failures, processing problems, or incompatibilities with existing lines.

- Prototypes for validation of packaging and auxiliary components.

- Evaluation of mechanical and functional behavior under real conditions.

- Development of technical solutions adapted to existing production processes.

Entrepreneurs, Startups, and New Businesses: choosing the right prototyping process from initial design to validated prototype and value proposition

For entrepreneurs, startups, and new industrial companies, prototyping is a key tool for transforming an idea into a tangible, validated product. At INFINITIA, prototyping reduces technical uncertainty, validates the concept, and provides functional evidence before making significant investments.

Prototypes facilitate business model validation, fundraising, and technical dialogue with manufacturers, investors, or industrial partners.

- Development of functional prototypes for proof of concept (PoC) testing, allowing feasibility to be assessed prior to final production.

- Technical validation prior to industrialization or supplier search.

- Technical support for the product’s evolution towards advanced stages.

R&D and Technological Development: 3d printing, prototyping methods and prototype manufacturing process from experimental prototype to production

In research and development projects, prototyping is an essential tool for validating technical hypotheses and exploring new solutions. INFINITIA collaborates with R&D departments and technology centers in the manufacture of experimental prototypes that enable real data to be obtained and technological development to advance.

- Custom prototypes for experimental testing and to create a prototype that meets the specific needs of the customer.

- Validation of new materials and construction solutions.

- Technical support for innovation and technology transfer projects.

INFINITIA as a strategic partner in prototyping and manufacturing industrial prototypes: innovation, reliability, and technical validation

The future of industrial prototyping is marked by the incorporation of new manufacturing technologies, the digitization of processes, and the growing use of prototypes as a tool for innovation. INFINITIA remains at the forefront of these trends, applying advanced additive manufacturing solutions, hybrid processes, and validation methodologies that accelerate the development of more efficient, reliable products tailored to market demands. This approach is particularly relevant in an increasingly competitive industrial environment, where speed and precision in the design and development of new products make all the difference.

Relying on INFINITIA for prototyping and prototype manufacturing provides high added value to companies by combining technical knowledge, advanced equipment, and a methodology focused on risk reduction and continuous improvement. This service allows organizations to move forward with greater confidence in the development of their products, optimizing resources and ensuring a robust transition from the initial idea to industrialization.